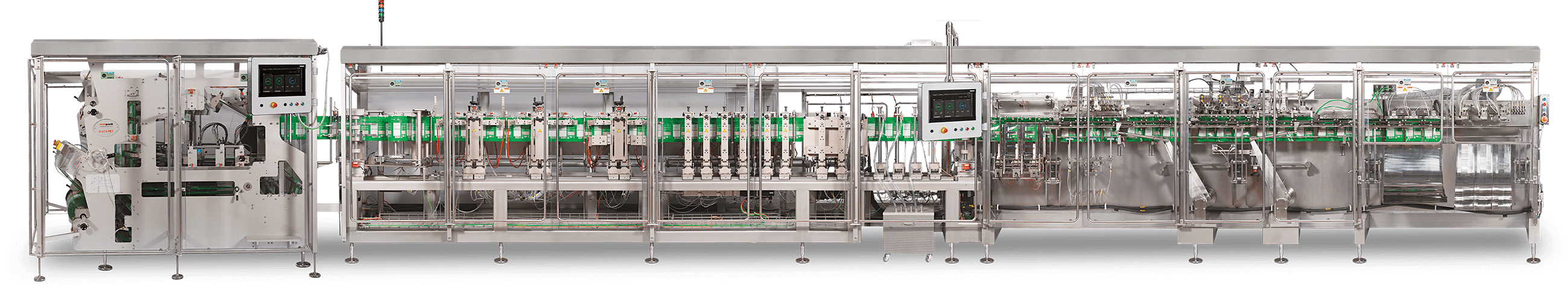

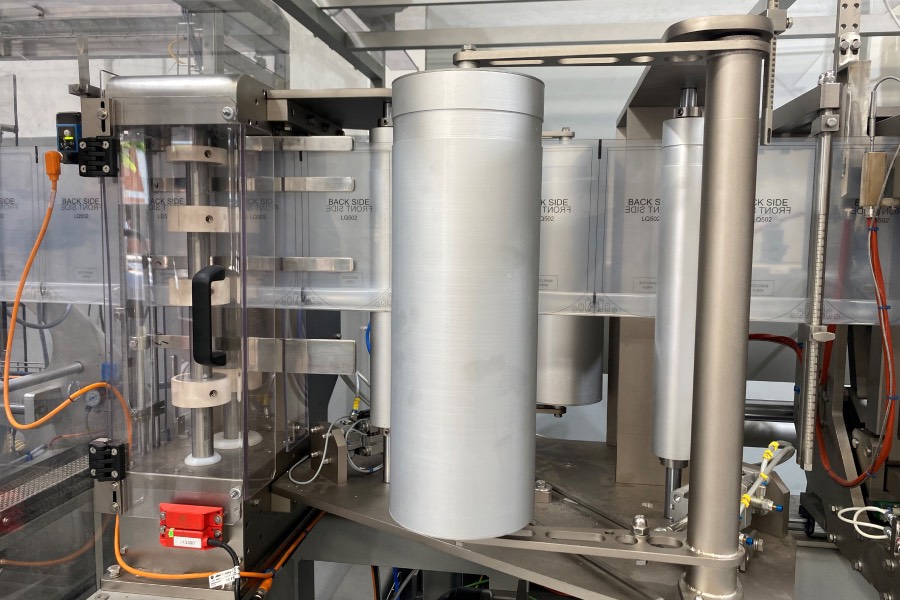

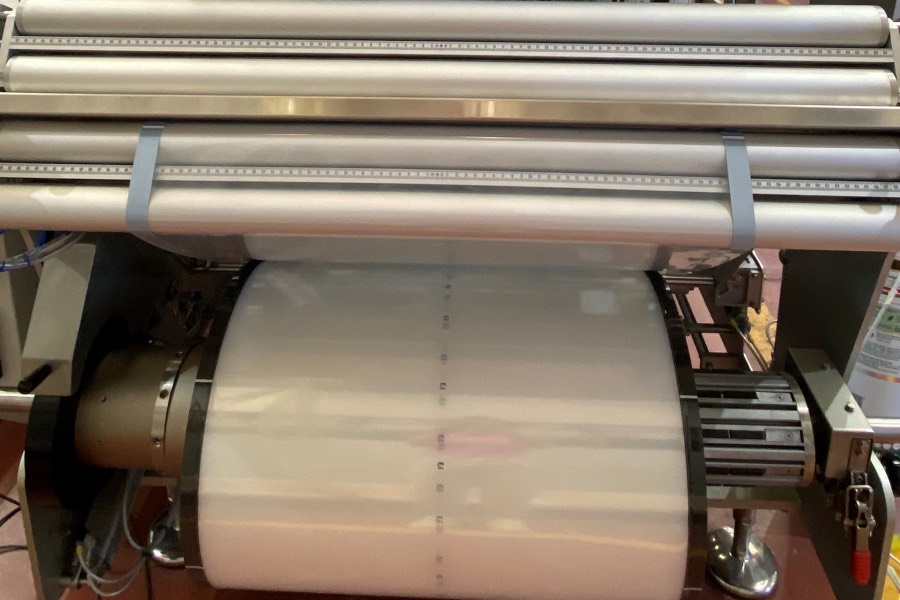

Mespack H570 Triplex solution forms and fills pouches with a maximum width up to 190mm and a maximum output of 180 pouches per minute. It complies with simplicity and robustness standards of Mespack design. It is designed to offer solutions for big stand-up and flat pouch formats.