Unwinder section

Transport section

Liquids

Solids

Granules

Powders

Reject section

Exit section

Unwinder section

Transport section

Liquids

Solids

Granules

Powders

Reject section

Exit section

This stick pack packaging machine is extensively used across various industries including, food or diet products, home and personal care, confectionary, and pharmaceutical, among others. The MS machine can be equipped with multiple dosing system configurations as well as special motorized systems for easy cleaning. Furthermore, it offers options that can be installed in the machine upon request, such as full-servo machines, ATEX compliance, laminar flow, a film sterilization systems, laser coders, scorers, among others. Our objective is to continue being a leading market supplier by providing outstanding machines suitable for a wide range of products that demand high speed and reliable production.

Our single-serve packaging offers a diverse range of stick packs, catering to various preferences and requirements. Stick packs have proven to be a successful format for single-serving packaging. Different stick packs formats are available, depending on the demands of the customer: bottle shaped stick packs, stick packs with two or more products, and twin stick packs.

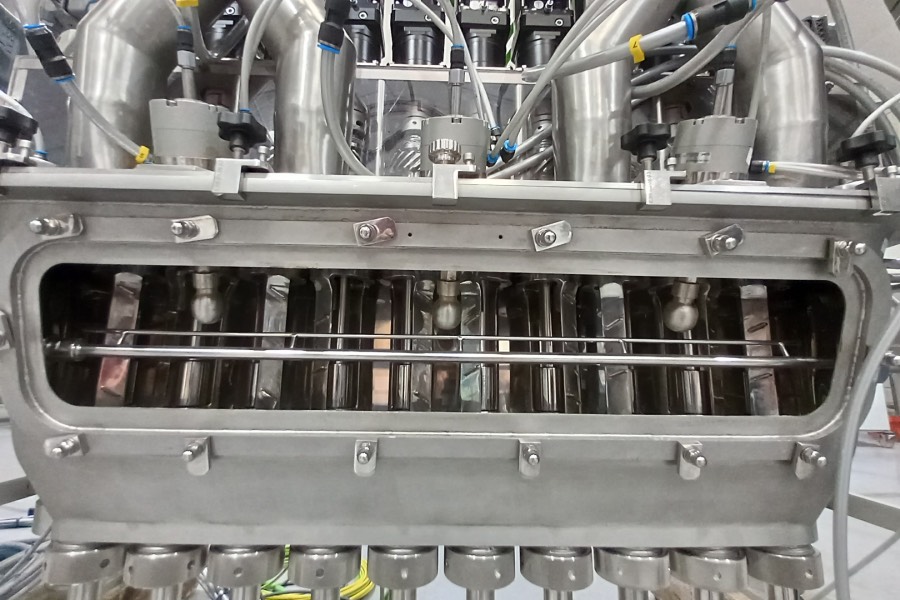

Due to the easy-open design of sealing jaws, machine maintenance can be easily performed.

Our special filling system is designed to avoid all types of product splash or foam on the horizontal seal. The simultaneous movement increases the sealing time of up to 40%.

Our vertical machines have an individual exit chute with reject possibility, which saves waste material.

The printing or coding area of MS Series is integrated to the machine unwinder, so there is no additional protection needed. Moreover, the support for this area is independent to avoid any possible vibrations.

Our special filling system is designed to avoid all types of product splash or foam on the horizontal seal. The simultaneous movement increases the sealing time of up to 40%.

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.