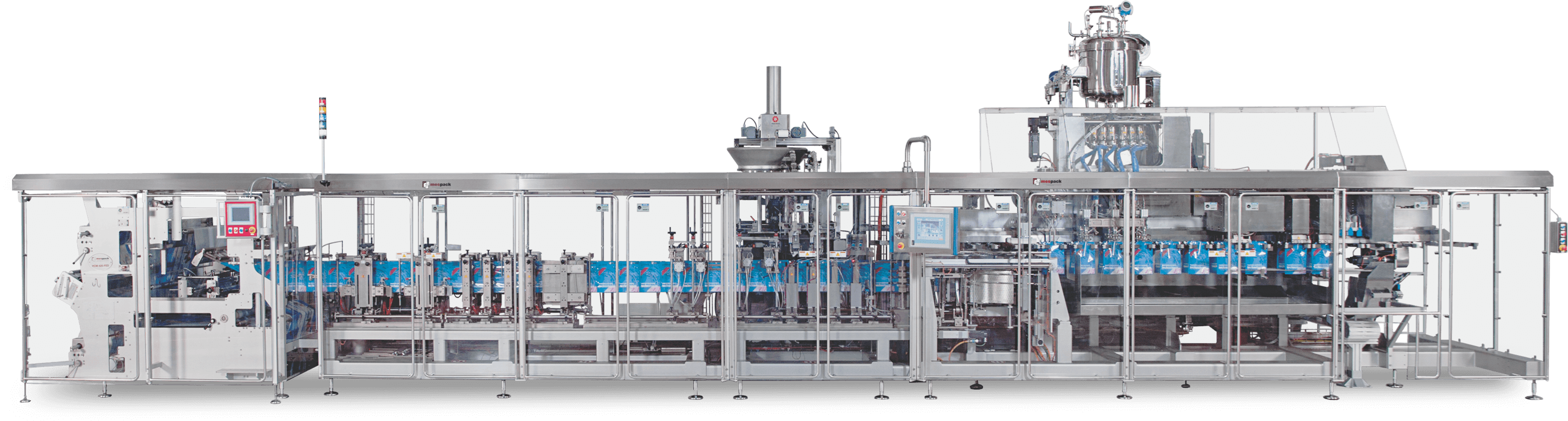

Unwinder section

Forming section

Tap corner aplicator section

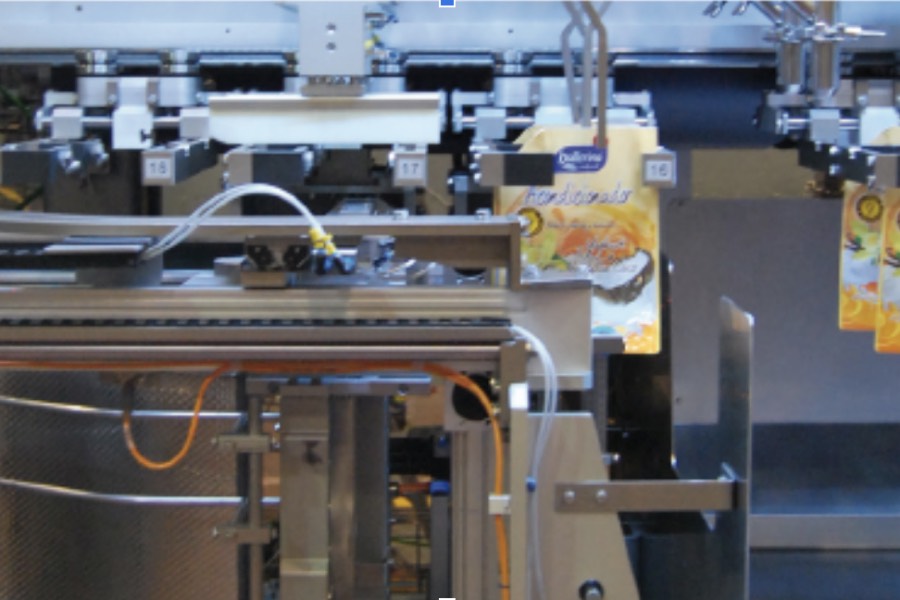

Transport section

Pouch exit section

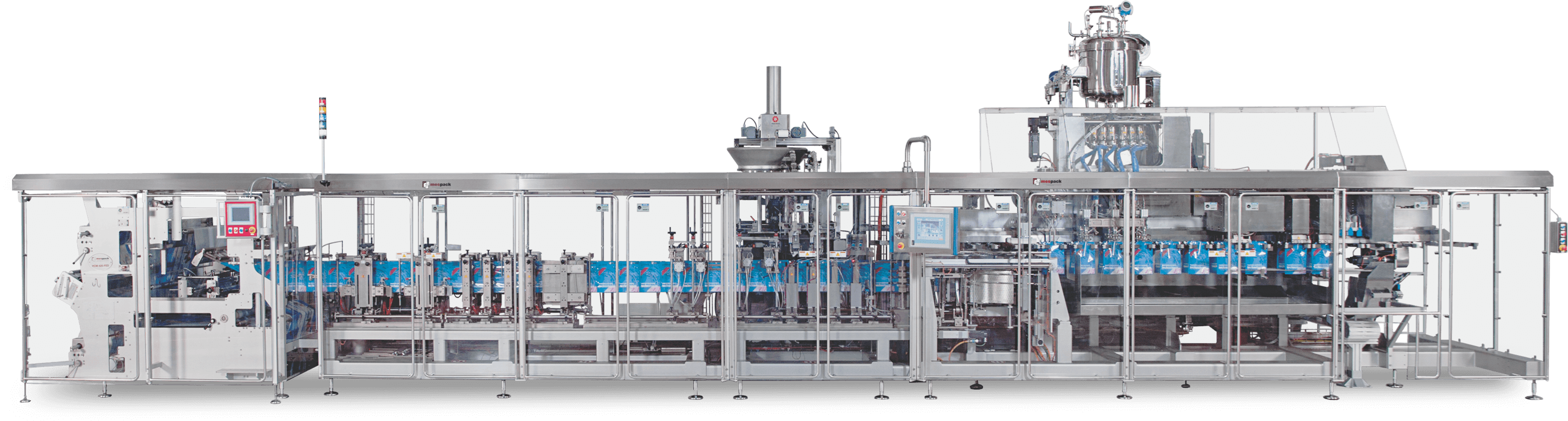

Unwinder section

Forming section

Tap corner aplicator section

Transport section

Pouch exit section

The fastest and most flexible horizontal packaging machine on the market. It combines a patented intermittent and continuous motion, capable of producing 150 pouches per minute. The HCM will allow you to present your product with the most innovative design. All models allow the installation of top and side cap applicators, zipper applicator, straw applicator, total inert gas chambers, as well as other customized accessories. The machine can also be supplied with any dosing system and accessory upon request.

The grippers width of all Mespack Grippers Management System (MGMS) is adjustable from the HMI. Auto-positioning of all the machine`s rear grippers allows for perfect clearance of the filling area, as well as adequately cleaned and sanitized.

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.