Mespack offers a wide variety of closure systems for the flexible pouches. Our objetctive is to provide complete and customized packaging solutions according to the needs of our customers and the market.

The zipper applicator system is composed of:

The edge cap applicator is composed of:

The top cap applicator is composed of:

The ultrasonic front cap application system is located in the unwinder. The cap is applied while the film is flat, prior to pouch formation. This system is composed of:

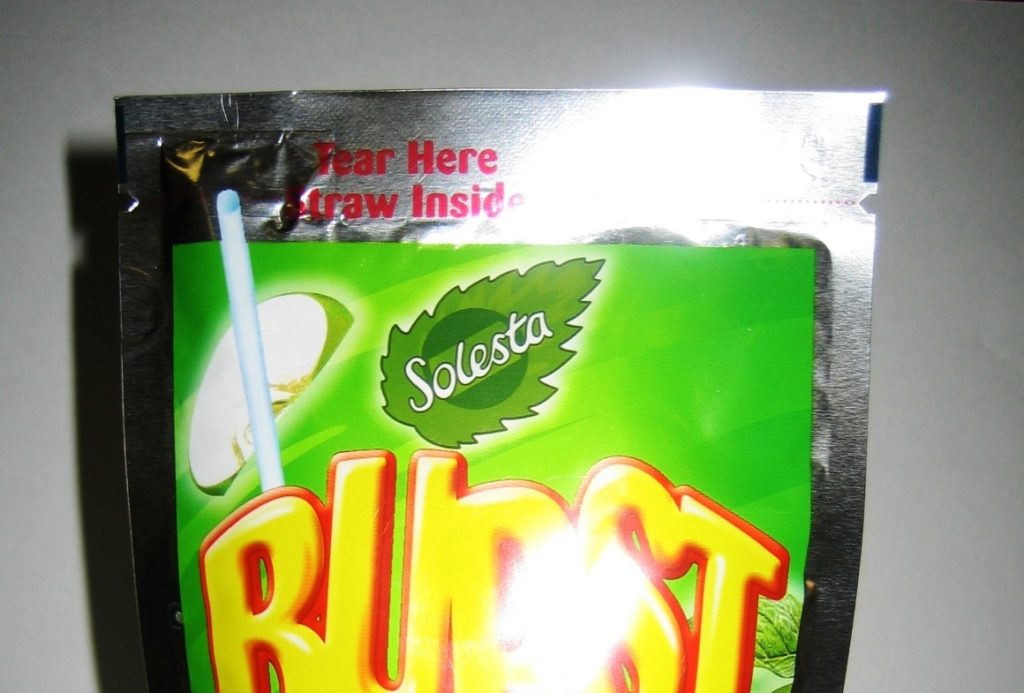

The straw feeding system consists of a frame with independent protections. In this structure, there is a special hopper for straws that is connected to a step by step system, which guides the straw to the introduction funnel.

Once the straw is introduced, a special jaw makes a small welding point to fix the straw inside the pouch and prevent it from floating during the filling of the product, thus avoiding problems in the top seal.

This system includes an automatic correction device to insert the straw correctly into the pouch, and allows for a rapid adjustment, in case a format change is required.

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.