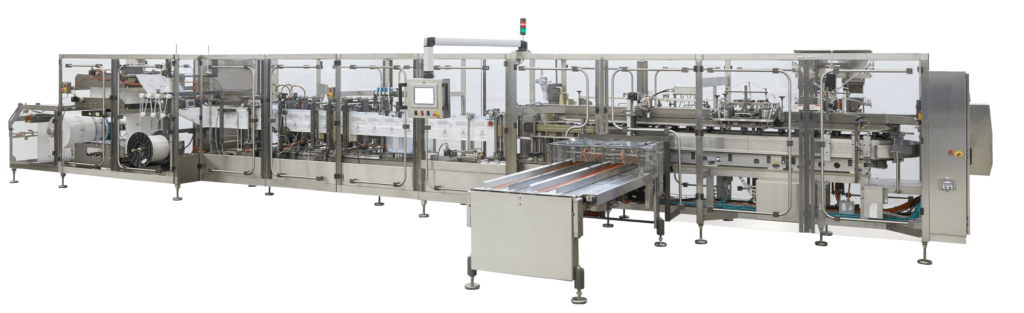

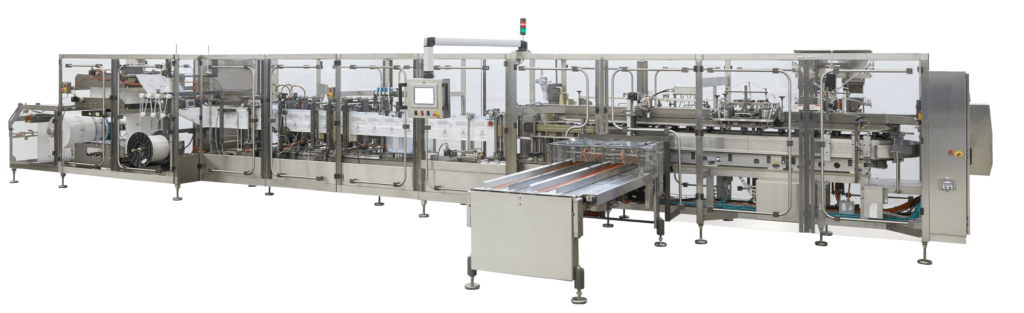

This series gives manufacturers a tremendous range of easily configurable options in a single high-performance solution. As a result, it is also considered an entry-level machine, despite its two working modes, pre-made and roll-stock packaging.

The IMH Series machines are highly adaptable, allowing for easy customization to meet the unique requirements of customers. These machines can be stretched to accommodate multiple filling methods, offering flexibility of any desired number of filling stations.

This series of Horizontal Packaging Machine utilizes Traveling Funnel System on filling stations, which are filled by a timing hopper. This system significantly increases the speed of the machine. Furthermore, the funnels offer toolless changeovers for quick replacements.

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

An edge computer, placed in the machine cabinet, is responsible for collecting and sending data to the cloud through an internet connection to be stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the machine’s data, belonging to the same customer, can be consolidated in a unique Mespack Athena dashboard view.