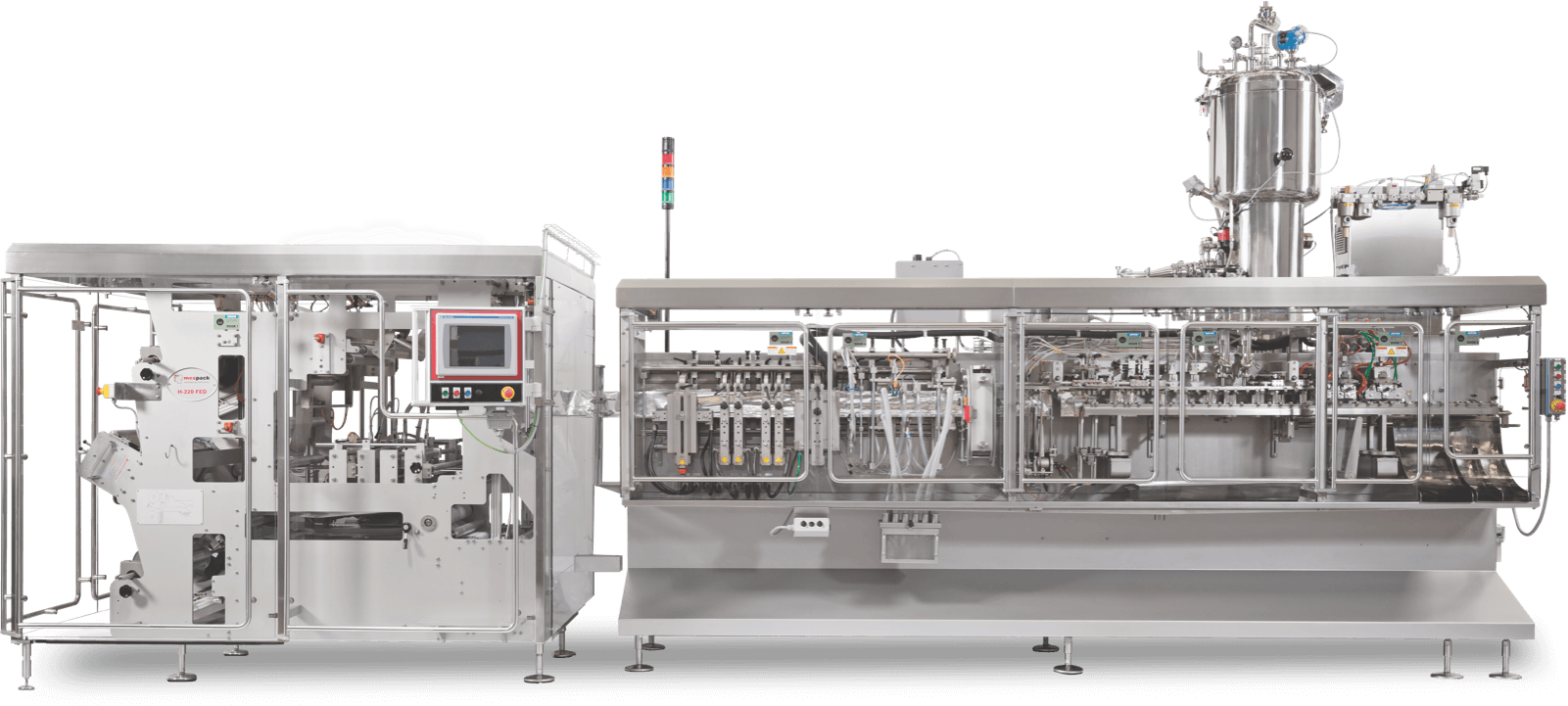

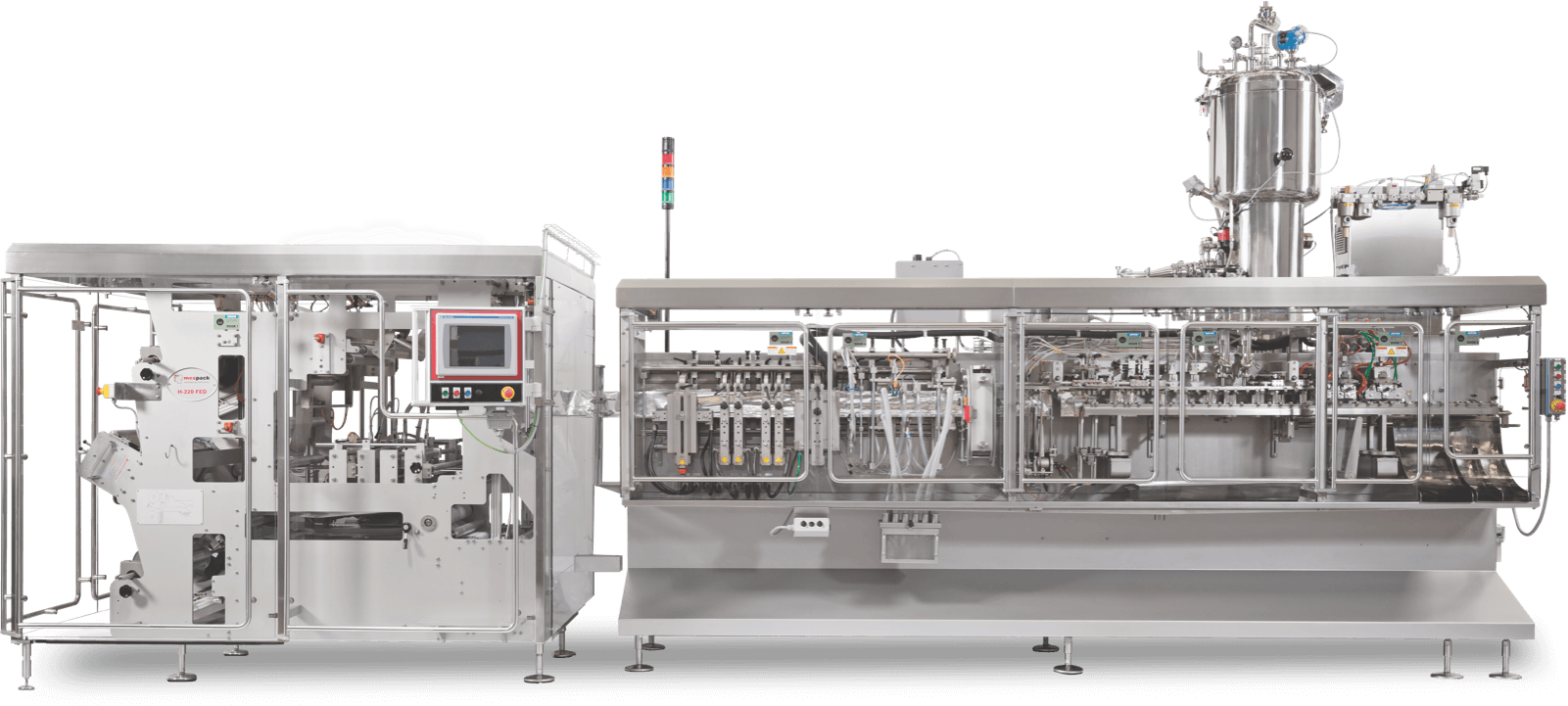

The horizontal packaging equipment to fill multicomponent pouches H260 has been designed complying with the simplicity and robustness standards of Mespack.

The horizontal packaging equipment to fill multicomponent pouches H260 has been designed complying with the simplicity and robustness standards of Mespack.

* Some of the items listed are optionals

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Max. Volume (cc) | 2000 | 750 | 150 | 2500 | 750 |

| Max. Output (p.p.m.) | 75 | 150 | 280 | 65 | 130 |

| AxB max (mm) | 270 x 300 | 130 x 300 | 65 x 240 | 270 x 300 | 130 x 300 |

| AxB min (mm) | 80 x 100 | 60 x 100 | 60 x 100 | 80 x 100 | 70 x 100 |

| Filling Stations | 5 | 5 | 2 | 5 | 5 |

The final speed will depend on product and film characteristics, it may change according to projects.

A wide range of dosing systems for all types of products on the market. More information

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Liquid / Pasty | |||||

| Pieces | |||||

| Powder | |||||

| Granules |

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Zipper | |||||

| Corner Spout | |||||

| Top Spout | |||||

| Frontal Spout | |||||

| Straw Applic. |

Let automation to enhance your machine downtime. More information

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Automatic Changeover | |||||

| Quick Changeover | |||||

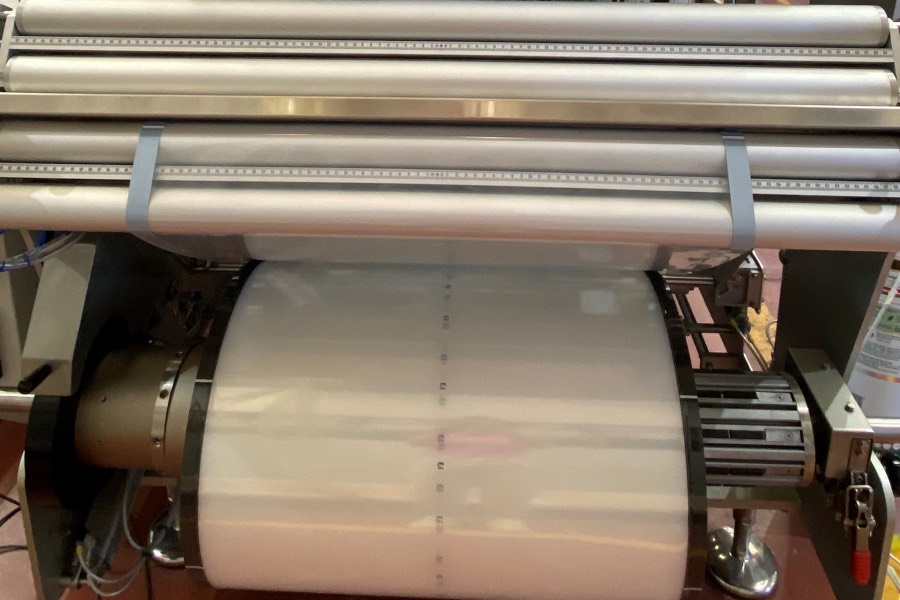

| Autosplice Unwinder |

Find your perfect fit for all your designs. More information

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Die cut (Shaped Pouch) | |||||

| Tear notch | |||||

| Eurohole | |||||

| Hole Punch | |||||

| Double Scissors | |||||

| Laser cut | |||||

| Round edges |

One coding system for each project. More information

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Laser | |||||

| Inkjet | |||||

| Thermo transfer | |||||

| Emboss Coder |

Do you need a non-bacterial atmosphere? Mespack offers all that you need. More information

| Machines | H260 S | H260 D | H260 4 | H260 FE | H260 FED |

|---|---|---|---|---|---|

| Gas Flush | |||||

| Laminar flow | |||||

| UV Lamp | |||||

| Washdown |

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.