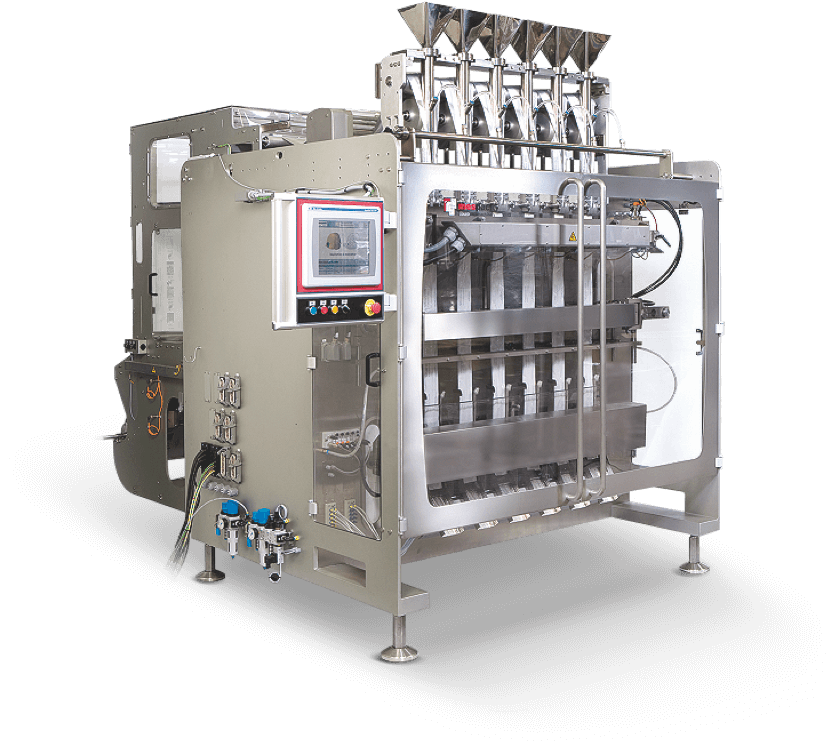

Mespack continues to lead the market with the VFFS multilane packaging machine for big format stick pack MS-1200. It is an outstanding machine for many types of products that need high speed dedicated production.

Designed to run reels up to 1200 mm in width, this machine features new servo drive technology and hygienic design.

Ideal for food or diet products, home & personal care applications, confectionaries, pharmaceuticals and more.