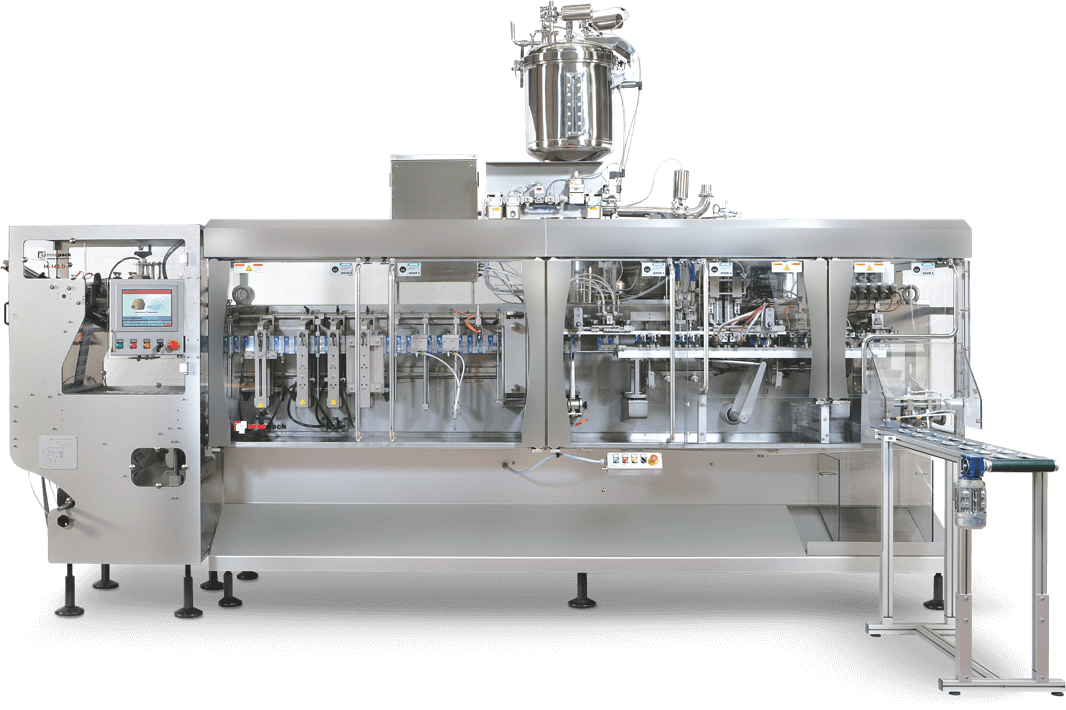

Mespack H145 is able to form, fill and seal stand-up pouches up to 500 c.c. It is a low cost horizontal packaging equipment, up to 4 filling stations are available to this model.

The continued effort in R+D of Mespack to adapt our range of machines to the actual market demands allows us to offer a multitude of options at a fair price.