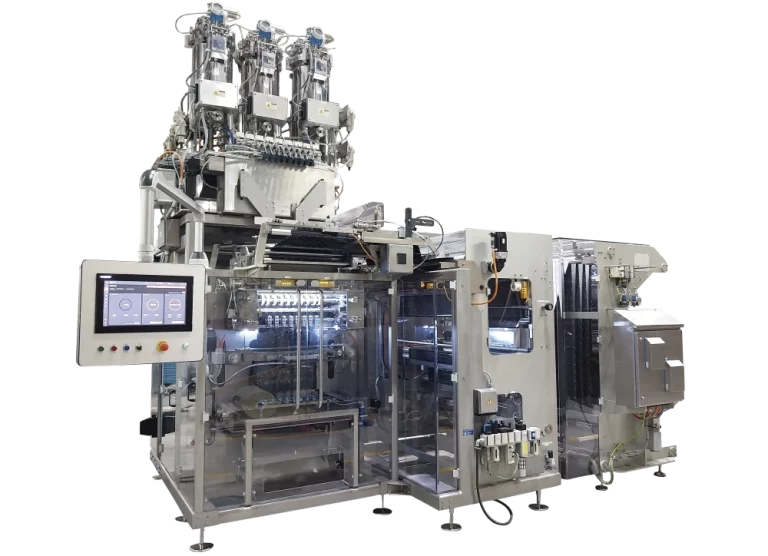

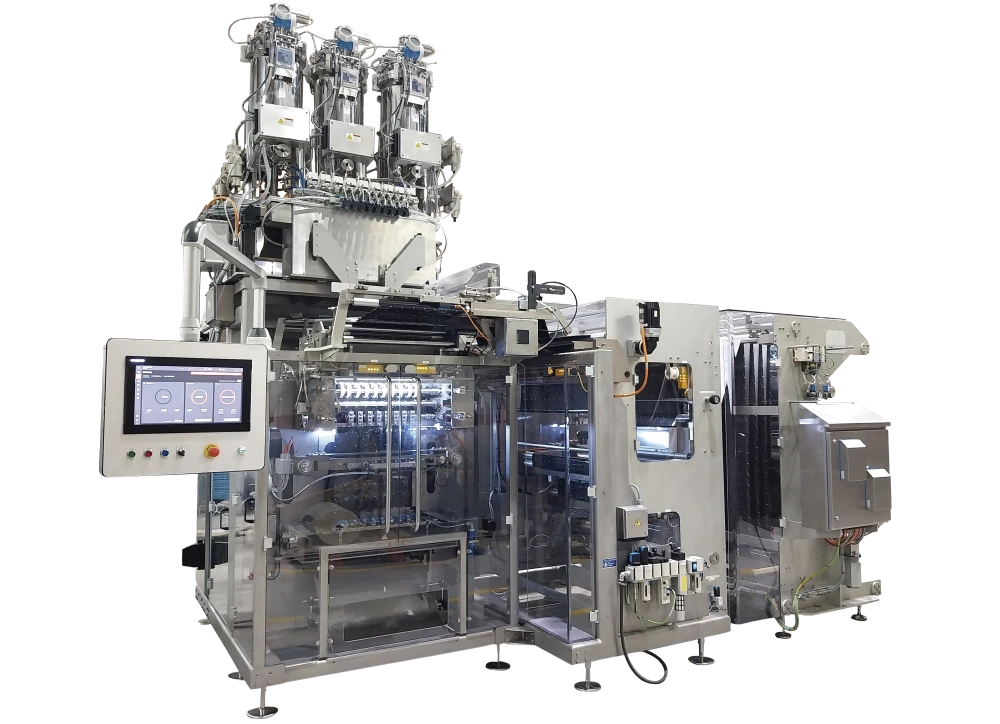

A machine that produces large 4-sided seal pouches with a vertical multilane solution that has a continuous sealing system.

The MLC1200 machine model is a vertical multilane for 4-side sealed flat sachet. The machine can produce large formats with a reduced footprint. The continuous sealing system, which can produce longer pouches for bigger filling doses, is the primary feature of the MLC1200. It produces pouches for liquid, pasty, granule or piece products. Additionaly, the MLC1200 operates with both automatic and quick changeovers, thus simultaneously reducing operational times and producing multiple formats. The MLC is ideal for all food products (including diet), home and personal care applications, confectionaries, pharmaceuticals, among others.