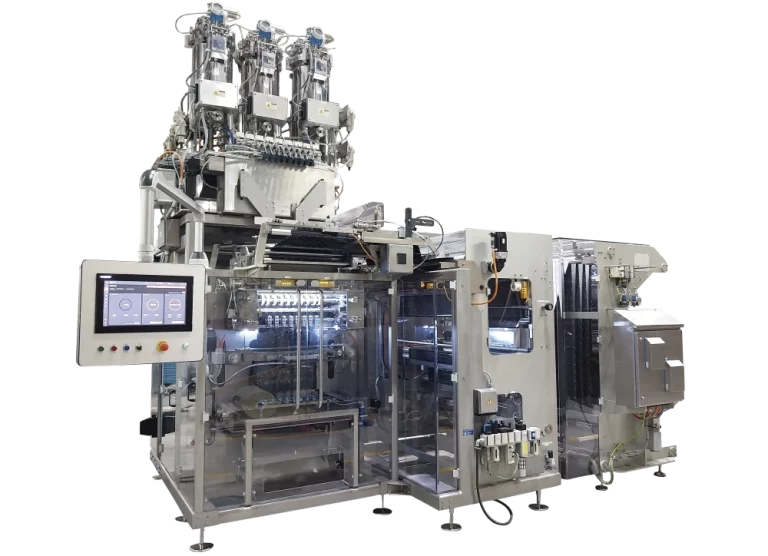

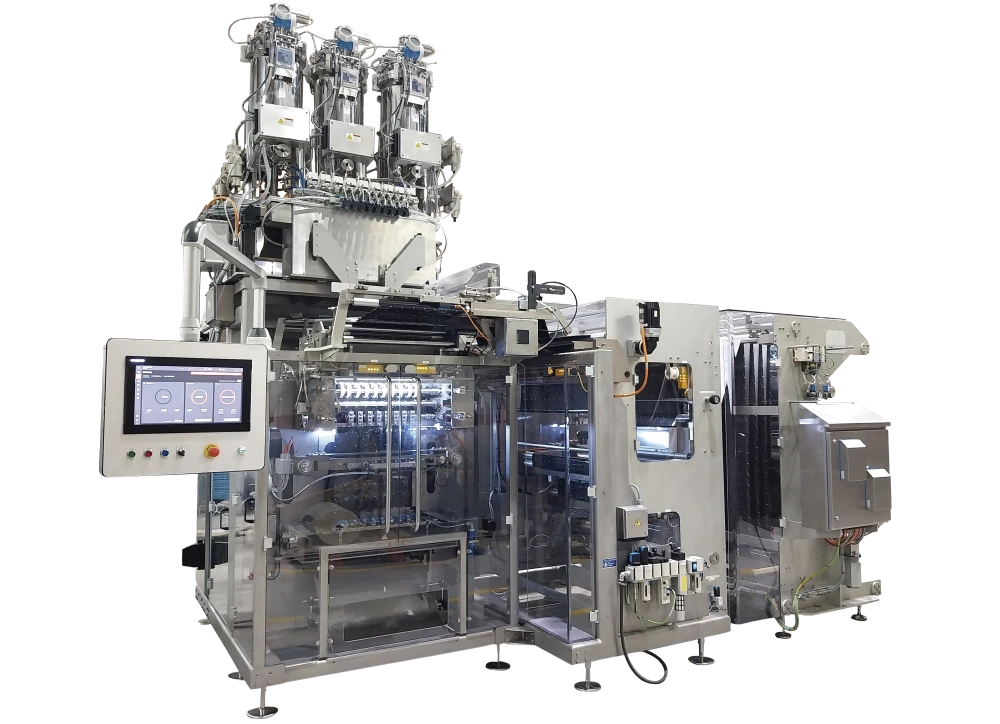

The MLC1000 is a multilane flat sachet machine for large formats. This machine is specially designed to produce substantial quantities of large formats with a reduced footprint. It can produce pouches for liquid, pasty, granule or piece products. The 4-sided sealed pouch is the primary pouch format best suited for this machine. The fundamental feature of the MLC is the continuous sealing system, which allows for the production of longer pouches for bigger filling doses. The MLC is ideal for all food products (including), home and personal care applications, confectionaries, pharmaceuticals, among others. The machine offers a full-servo motorized solution. Contingent upon the required width of the pouch to be produced, various quantitative inclusions of production lines are possible. Furthermore, it can be fitted to operate with sustainable materials, thus adapting your business to the new developments related to the sustainability of packaging solutions.