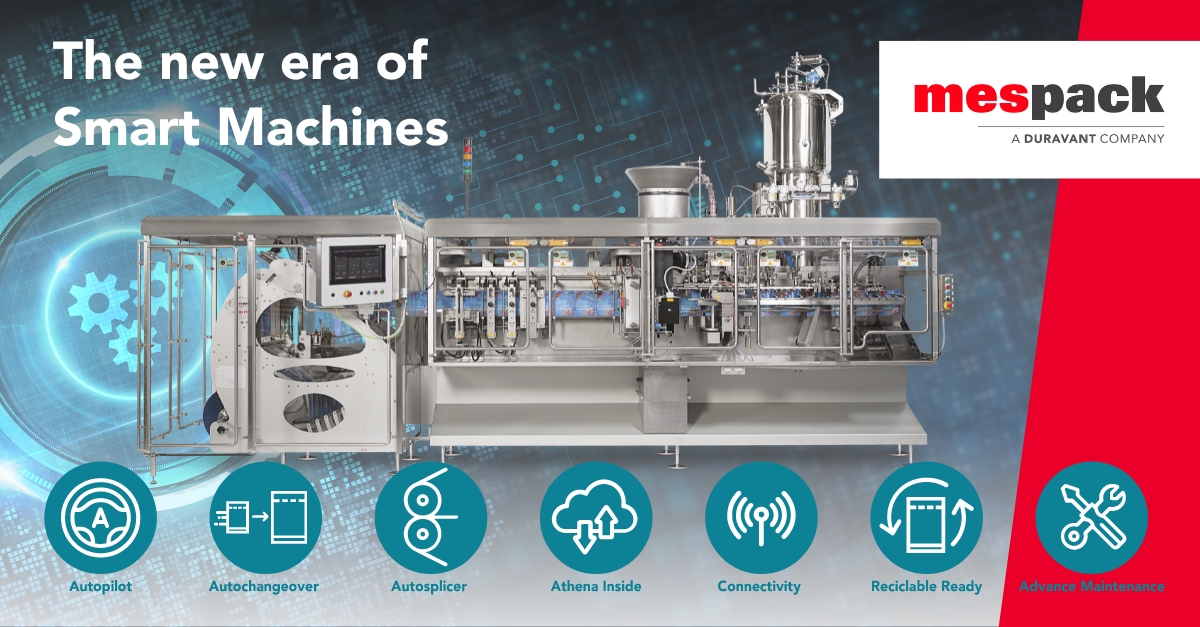

The era of smart machines has many implications in regard to equipment, such as better connection as well as more flexibility, efficiency, and safety

The term ‘Smart Machine’ implies an equipment that is better connected, more flexible, more efficient, and safe. Based upon a collection of smart, connected roducts, it maximizes efficiency via intuitive collaboration with its users.

Autopilot is Mespack’s new state of the art technology that allows the machine to automatically adjust the optimum operating temperature and pressure parameters (depending on the type of recyclable film).

• Less changeover time

• Highly skilled operators are NOT required

• Online reel control for interior variation

• Operator’s require less labor hours for testing new material

Autosplicer is an automatic splicing technology that was developed to avoid machine downtime and reduce material waste during roll changes.

• Save 5 to 10 minutes for every 2 hours of production

• Reduce the operator’s working hours in format changes

• Highly skilled operators are NOT required

Advance Maintenance. Predictive maintenance analyzes the condition of the piece based on its operation, wear, and tear; it is able to predict forthcoming breakdown. Preventive maintenance pertains to the periodic performance of scheduled maintenance according to the useful life of each part in order to avoid breakdowns and production downtime.

Recyclable Ready Mespack machines are designed to be easily adaptable to operate with recyclable of compostable material and paper. They have the ability to not only work with both new materials and traditional laminates, but also maintain efficiency and consistently guarantee superior performance.

Connectivity is possible thanks to Athena Cloud. You can have production data visibility at any time and anywhere around the World. Furthermore, several machines in the same or different production plants can be supervised from any device such as a PC, tablet, or mobile phone, enabling comparisons across machines or plants and receiving production alerts.

Athena is a digital platform aimed to give our clients the power to maximize the value of their production data, due to its ability to perform a variety of tasks from machine control to data analytics.

Two solutions for data storage On-Premise/On-Cloud

On-premise consists of an industrial computer placed in the machine cabinet where all the data is stored and analyzed by Athena. It can be accessed through either a wire or wireless connection. No internet access is required. Whereas On-Cloud option, an edge computer, placed in the machine cabinet, is responsible for collecting and sending data to the cloud through an internet connection.

Data analist and machine control

Collects real time data from the machine and stores it for analysis through an

intuitive dashboards It supports to our customers in making more reasonable

and better business decisions, as well as optimizing the performance of their machines.

Benefits

• State of the art hardware

• User friendly UX/ UI interface

• Reduces the operator learning curve

• 85% screen functionalities in a single click or less

• Operator’s empowerment

• Follows ISA 101 (visual comfort, ergonomics and UX)

• Same look and feel for all our machines portfolio

Savings and productivity improvement

• Increase throughput up to 4%

• Up to 3% increase of uptime

• Up to 1.5% improvement in quality

• Production cost improvement of up to 3%

• Reduces scrap of up to 3%

• Reduction of maintenance costs by up to 200 hours per year

Autochangeover allows an automatic changeover of the pouch format, thus helping to reduce machine downtime and increase the changeover accuracy.

• Reduces material waste in machine adjustment

• Reduces up to 20-40% in changeover time

• Reduces the operator’s labor hours in format changes Highly skilled operators are NOT required