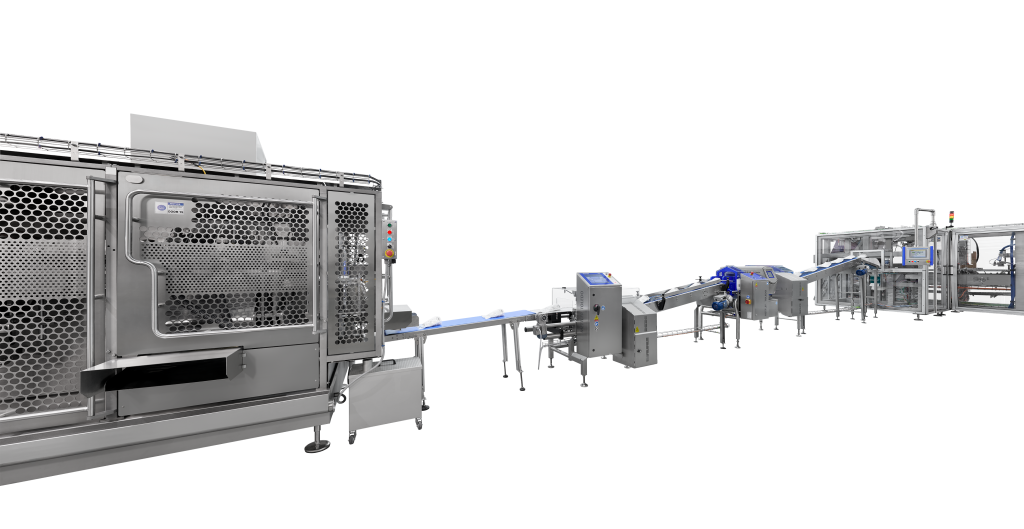

The latest Mespack turnkey project is a complete line that connects with a horizontal machine, the H440FED, which produces stand-up zipper pouches in a duplex configuration; this machine runs 100 pouches per minute with a special recyclable film.

As a duplex machine, stand-up pouches are double downloaded from the H440FED with an appropriate distance onto the acceleration belt, which facilitates the synchronization between the machine and the belt. The pouches are spaced apart, creating a distance that allows for better control before passing through the weight check point, metal detector or any other device required for the quality control process.

The procedure to secondary packaging can be extended according to the needs of the factory. As a result, we can also take charge of the conveyor system and the integration of various devices that may be required.

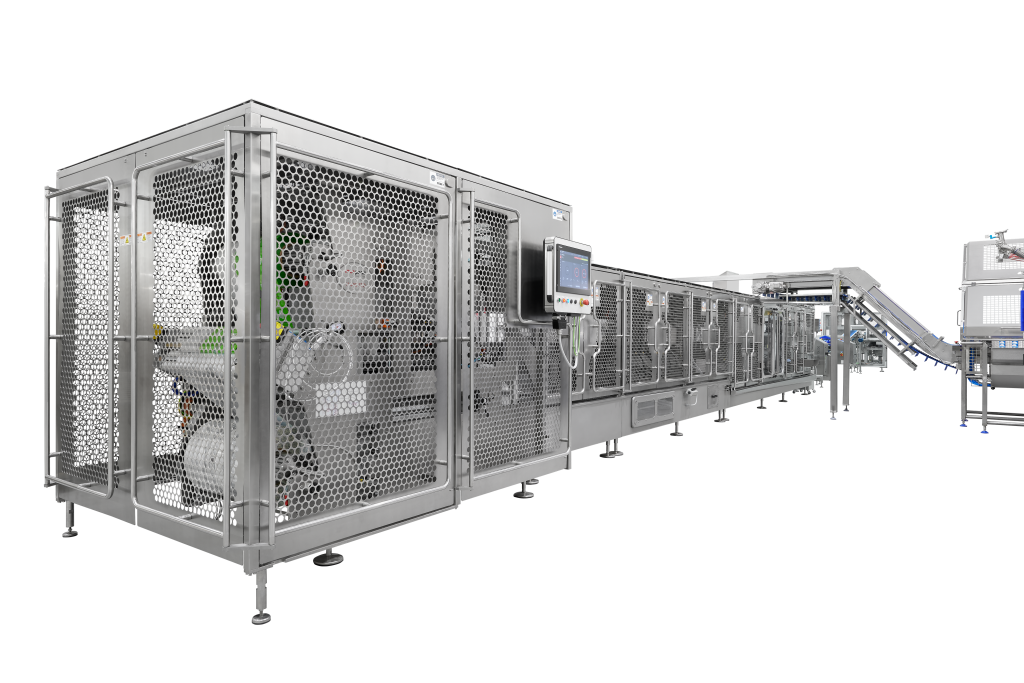

In this scenario, the WA7000 PRO, our case packing module for wraparound cases, produces six different format cases: 8 to 16 pouches with one or two columns in vertical position.

How does the turnkey project operate?

With the same care we have given primary packaging pouches, such as filtering through various devices and conveyors, at the infeed point, we carefully introduce each pouch into the racetrack system, which is responsible for counting and grouping pouches in accordance with each format.

Once the total quantity of pouches is prepared, the transfer arm keeps the pouches inside the U-shape of the case, which is waiting at the front of a standby station. After the case has been fed, the arm returns to its waiting position for the next group of pouches. Inside the wraparound machine, the case moves to the next station, and begins the case closure process. Once the case is closed, it proceeds to the next process: the palletizing stage. Furthermore, if the palletizing system is part of the complete line, Mespack can integrate this process.