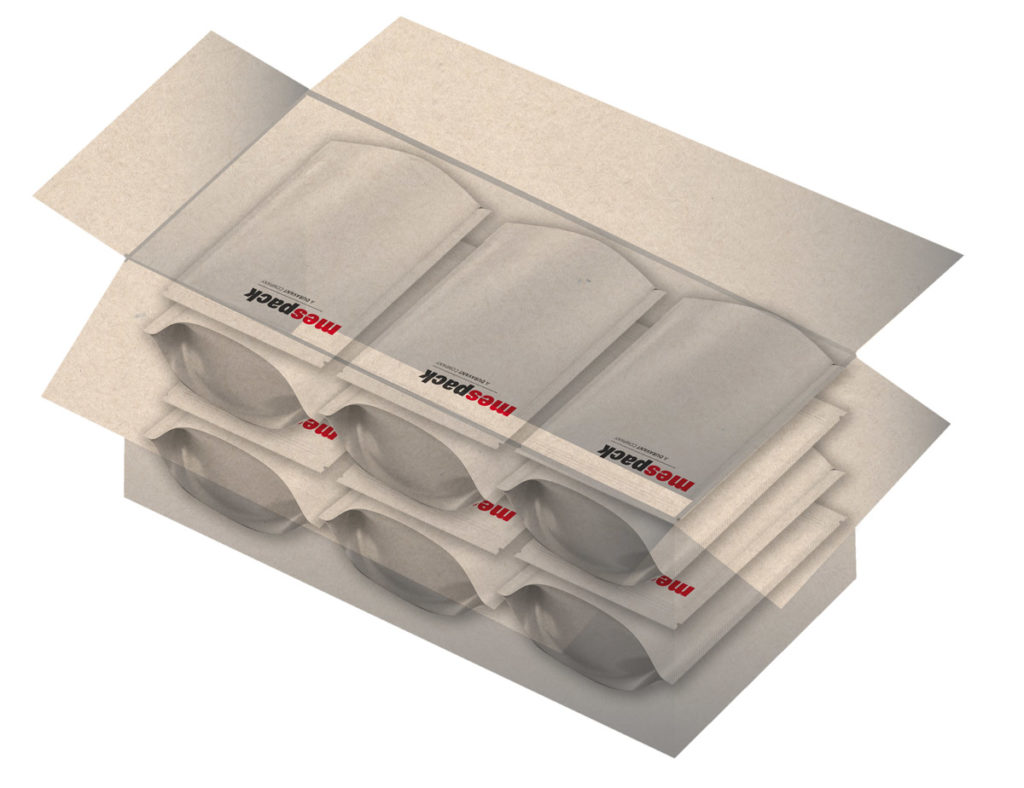

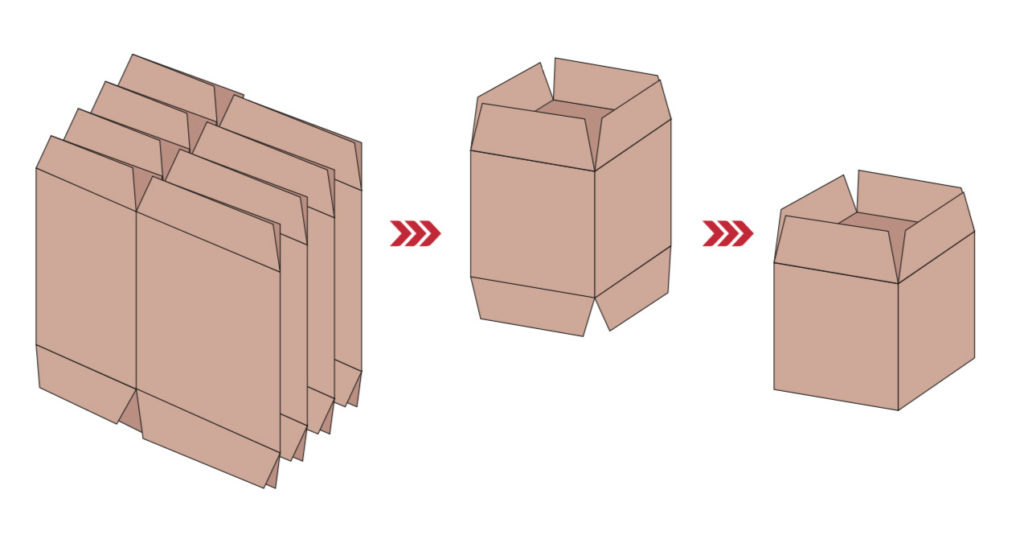

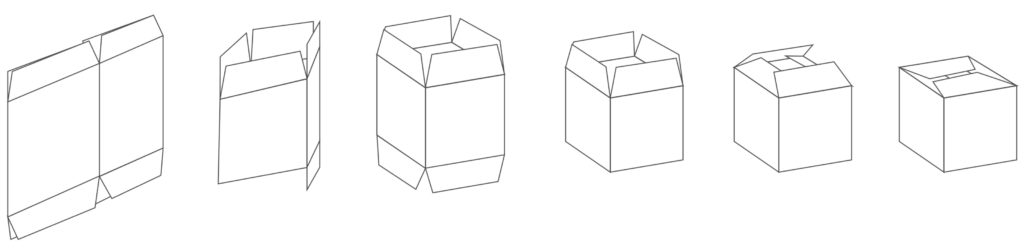

Secondary packaging plays an important role in the final step of a production process, being the most important protection given to the product during transportation. At Mespack, we provide Turnkey projects of flexible packaging into the market. One of our solutions is the American box packing module EF100, which consists of three equipments connected in one: case erector, picking, and case sealer. The flexible pouches can be grouped horizontally or vertically inside the boxes, and the maximum speed is up to 25 cases per minute.

Among the advantages of picking robots, we must highlight their small dimension, which makes these robots placable in very small spaces. Furthermore, their speed and precision operate well with rapid and high-volume productions. There are two types of robots applications, depending on the picking system: Delta and Cartesian. Both of them, can grasp and transport more than one unit at a time to the box by means of multiple pickings.

| MACHINE | Output Cases/minute | Format Max LxWxH (mm) | Format Min LxWxH (mm) | Sealing System |

|---|---|---|---|---|

| EF100 | 25 | 600X400X600 | 600 max 240 min |

400 max 160 min |

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.