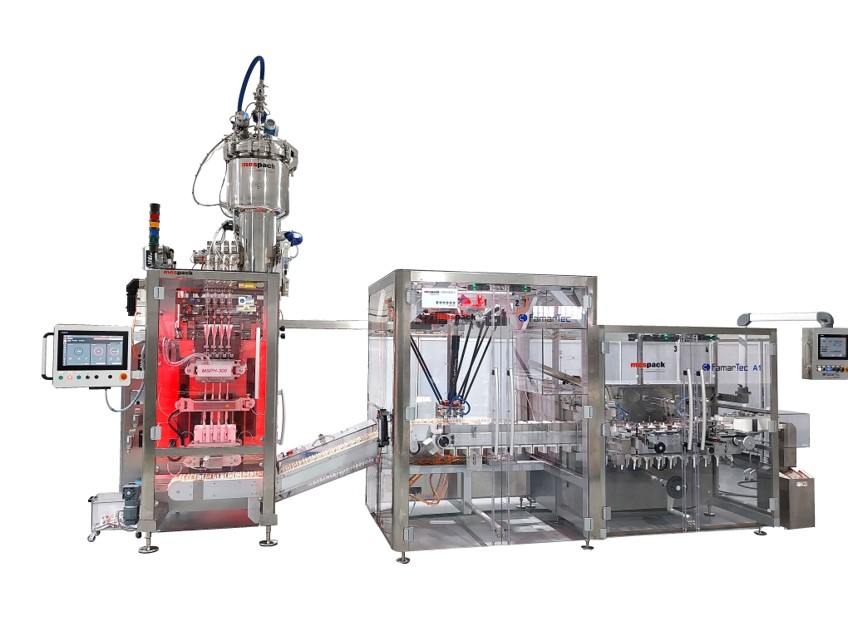

- A new vertical form-fill-seal machine, exclusively developed for pharmaceutical products, is integrated with Famartec’s cartoning machine, in order to produce give an integrated solution

- The highest production speed solution in continuous motion, with industry leading efficiencies, is capable to produce up to 200 pouches per minute

Mespack, a leading manufacturer of innovative and sustainable flexible packaging solutions, is pleased to announce its participation in Pack Expo 2023, one of the most significant fairs of the packaging industry, which will take place in Las Vegas (USA). At this edition of the event, the company will strengthen its role as a leading company of the flexible packaging industry, due to its commitment to develop sustainable and smart machines.

As a highlight of the Mespack Pack Expo exhibit, the novelties immerse the visitors in an awe-inspiring experience of sustainability, high performance, connectivity, and integrated solutions.

After approximately 30 years in the flexible packaging market, Mespack has become a one-stop-shop player with the industry’s largest product portfolio, offering horizontal (roll-stock, pre-made, and hybrid) and vertical equipment to produce sachets, stick packs, stand-up pouches, water soluble pod, various film-based packaging, and end-of-line solutions with premium services worldwide.

The pharmaceutical industry is another key sector that is increasingly demanding complete solutions. For this market, Mespack has been collaborating with Famartec in order to offer a high-quality integrated solution. At Pack Expo, Mespack will introduce its new vertical form-fill-seal machine: MSPH series. This machinery has been exclusively developed for pharmaceutical products, and is integrated with Famartec’s cartoning machine, in order to produce stick packs and insert them into cartons. This the vertical form-fill-seal machine for stick pack pharmaceutical products, is able to produce up to 840 sticks per minute. The MSPH series has been specially designed for the pharmaceutical industry and complies with specific regulations, such as GMP, GAMP5, FDA, and 21 CFR Part 11. In reference to documentation focused on pharmaceutics, this solution not only offers the execution of DQ, IQ, OQ, RA, but also the preparation of PQ and EN1020 standard 2.1 and 3.1 material certificates. Upon request, other forms of documentation can be prepared as well.

Additionaly, a CMR series is as well presents at Pack Expo Las Vegas, a high production speed solution with industry leading efficiencies: it represents the next generation in continuous motion technology with auto-changeover of 20 minutes. The CMR can be configured for a with range of filling applications. At speeds of up to 140 ppm, this series is a unique solution for a complex packaging environment with wide flexibility. The servo motor intelligence and unique continuous motion design generate the speed and efficiency needs for the customers that works on the pet food industry or general food where pieces are solid, such as dried food.

Furthermore, the company will present the improvements and developments to its highly acclaimed digital platform, Athena. This platform not only enables customers maximize the value of their production data, but performs tasks from machine control to data analytics as well. Since its launch, Athena has proven to be a key tool that elevates the efficiency of Mespack’s machinery; clients are able to achieve their business goals while maintaining complete control and obtaining the most from the data generated throughout their manufacturing process.

Once again, Mespack will feature its legendary partnership corner, “Wall of Fame”. This corner will showcase the most recent recyclable-ready packaging co-creations and projects with the company’s strategic partners in the sector: Amcor, Bobst, Comexi, Dow, Famartec, Hoffer, Menshen, Mondi, MonoSol, NeoCeram, Notpla ProAmpac, and Uflex, Additionally, this exhibition will be a discussion point for solutions focused on sustainability and the manner by which Mespack and these partnerships can support companies in making the shift towards more recyclable packaging.

In collaboration with Amcor and Menshen, Mespack has used its equipment to develop a new high-quality green spouted packaging. This solution is produced with Amcor’s AmPrima® PE Plus film and Menshen’s spout, both of which have a mono-polyethylene foundation. The evolution of this packaging is based on drop resistance improvement. Subsequently, this pouch is capable of holding 1L of liquid.

Recently, along with the rest of the partners Mespack has market launched, additional sustainable packaging solutions, particularly recyclable spouted stand-up pouches, which will be on display in the sustainability corner.

Conjointly with Mondi, Mespack has developed a new sustainable stand-up pouch of exceptional quality. This pouch is constructed with Mondi’s functional barrier paper 95/5 and printed with Comexi‘s D4 digital press.

Furthermore, within the framework of Mespack’s collaboration with ProAmpac, an H180FE machine was installed at the ProAmpac Collaboration and Innovation Center in Rochester, NY (USA). At the center, to test materials, applications, and technologies are tested together with customers. For the same purpose, the Dow Pack Studios, innovation center is also equipped with an H180FE machine as well.

Also this year, Mespack is will be presenting the a special gift: the “Golden Ticket”. Visitors to its the company’s booth will receive an invitation to visit one of the innovation center of Mespack, Dow or ProAmpac innovation centers to learn about their sustainable developments, receive advice and trainings, test recyclable materials and applications, view demonstrations of machinery on display, meet strategic industry partners, among other objectives.

Visitors will be able to view those novelties at Mespack’s Pack Expo booth C4034. The Pack Expo trade fair is one of the most respected and relevant exhibition of the packaging industry.