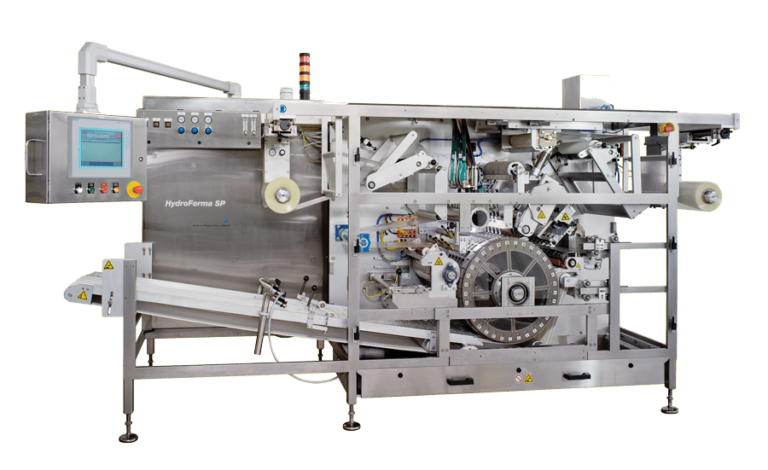

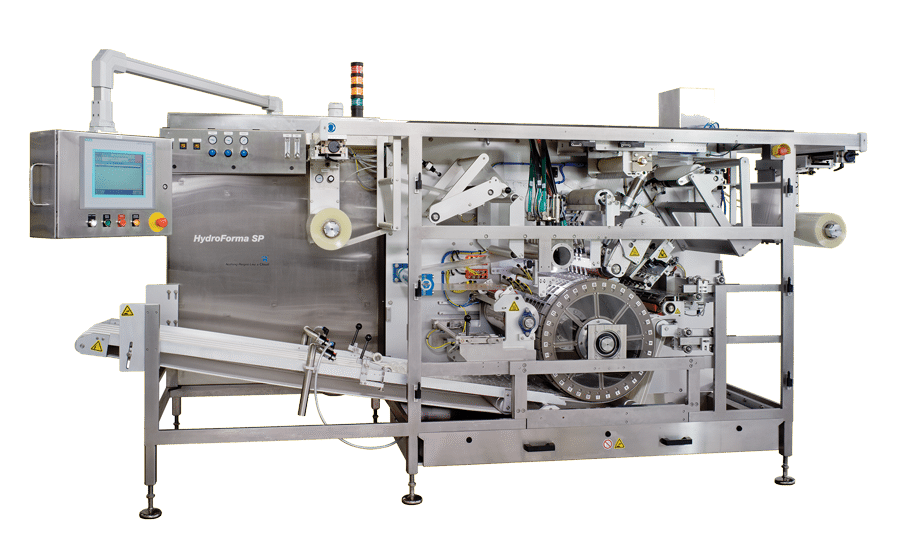

The Mespack Hydroforma 165,although it is a smaller solution with a competitive price, uses the same technology of our other industry-leading Hydroforma equipments. It produces 3 to 5 times the product per minute of our competitors vertical style machines with half the scrap waste of non-rotary machines.

All the engineering excellence and performance, in a smaller footprint. At half the speed of its big brother, the Hydroforma 165 is still one of the fastest machines available. With speeds of up to 1200 PPM, it is faster than other machines in the price range. It provides the same technology of our industry leading Hydroforma machine. It packages three to five times the pouches per minute of any competitive vertical style machine.