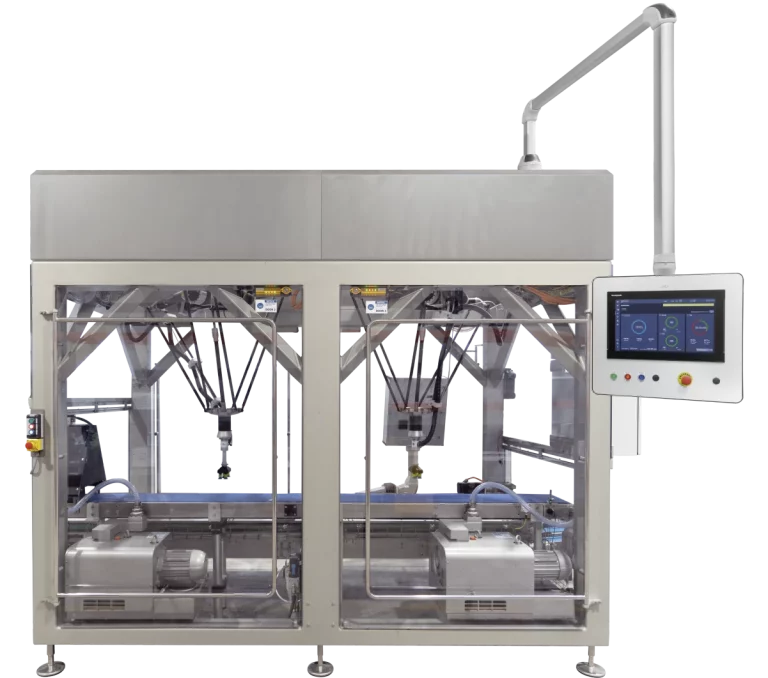

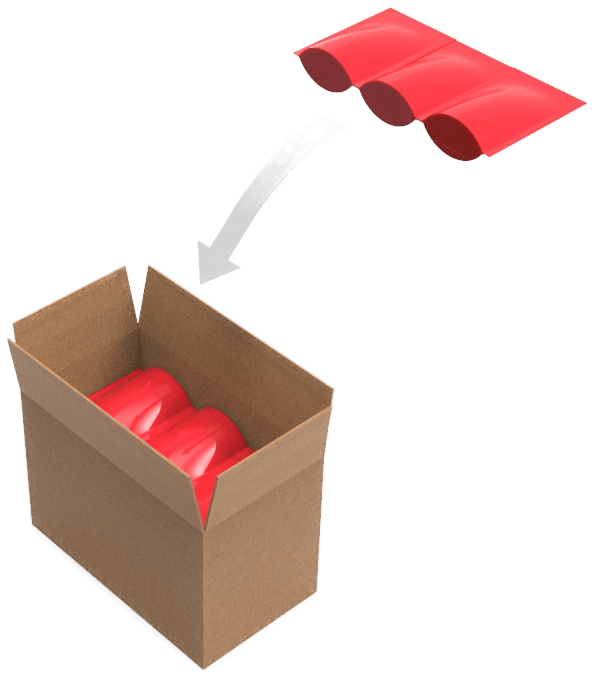

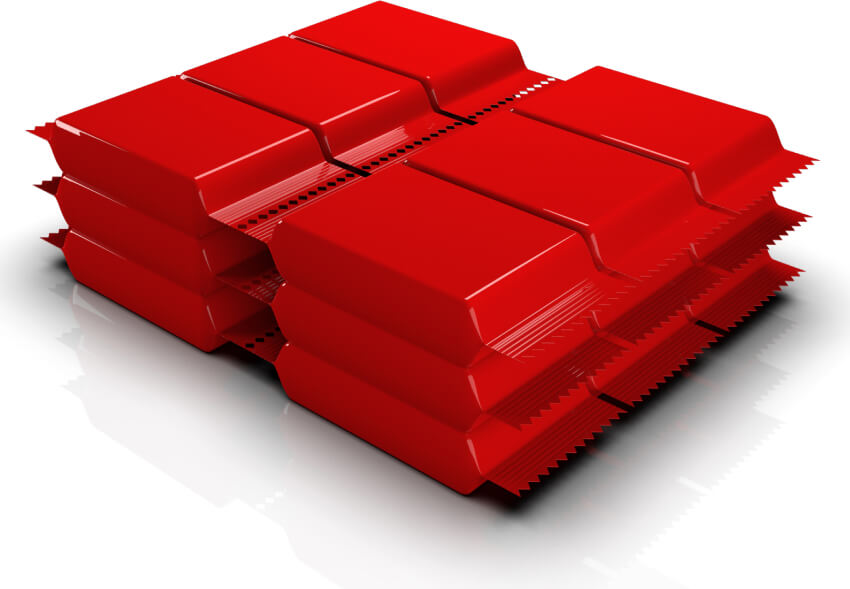

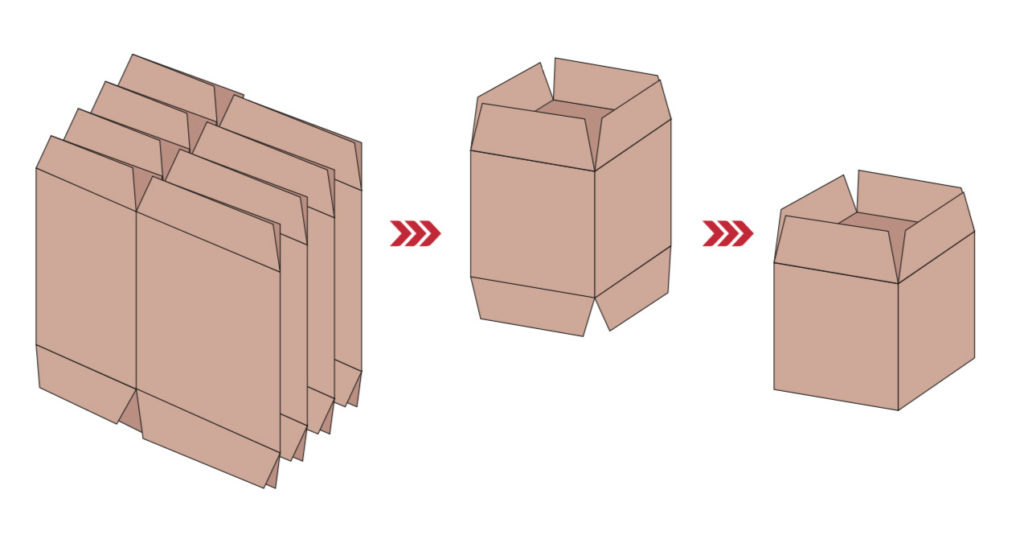

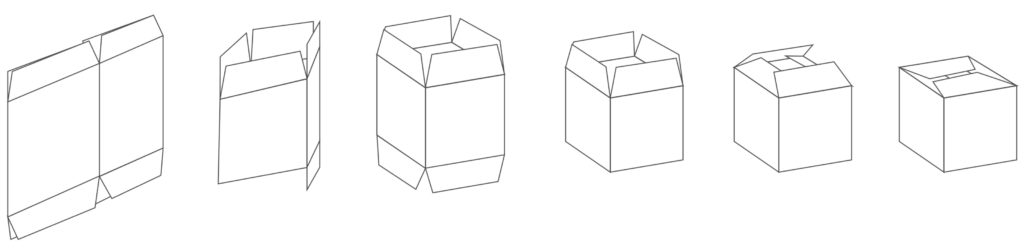

Introducing our advanced MCP Series, the ultimate solution for secondary packaging, designed to offer comprehensive turnkey solutions within the RSC market. Our MCP Series machines feature the latest, Delta Robot and full servo integration. This advanced equipment is not only versatile but also equipped with up to 4 picking modules, ensuring a significant boost in production speed. Moreover, our MCP Series seamlessly integrates with other essential components, such as the carton sealing machine and carton erector machine, providing a complete and efficient packaging solution. Elevate your production capabilities with the latest innovations in the MCP Series.