Forming section

Liquids

Solids

Granules

Powders

Exit section

Unwinder section

Reject section

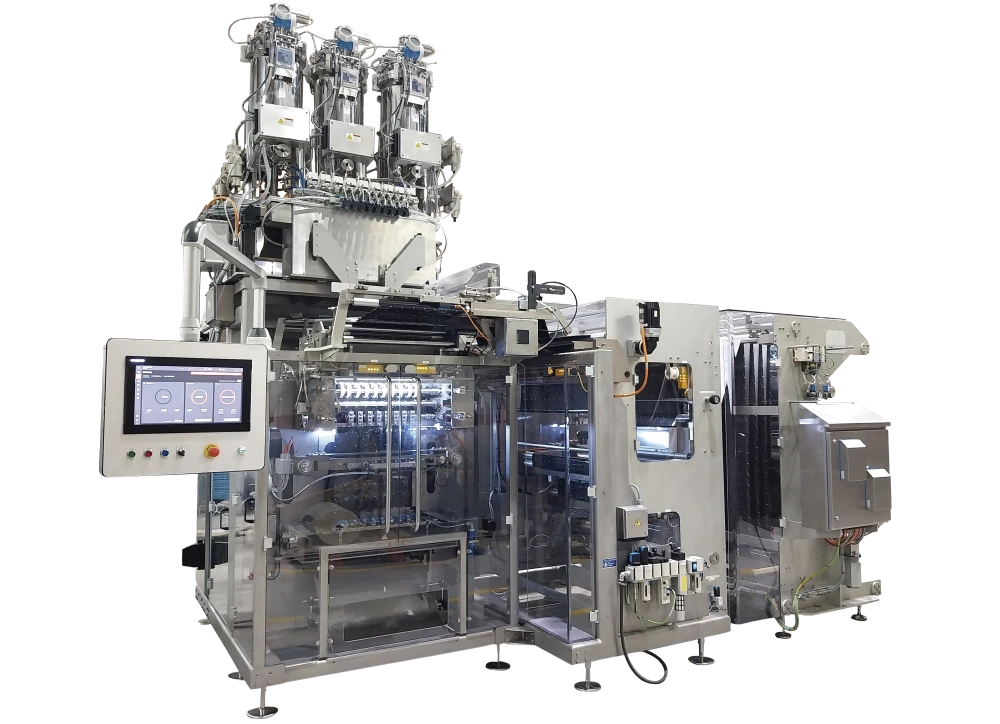

The MLC is a vertical multilane flat sachet machine for large formats. This machine is specially designed to produce substantial quantities of large formats with a reduced footprint. It can produce pouches for liquid, pasty, granule or piece products. The 4-sided sealed pouch is the primary pouch format best suited for this machine. The fundamental feature of the MLC is the continuous sealing system, which allows for the production of longer pouches for bigger filling doses. The MLC is ideal for all food products (including diet), home and personal care applications, confectionaries, pharmaceuticals, among others. The machine offers a full-servo motorized solution. Contingent upon the required width of the pouch to be produced, various quantitative inclusions of production lines are possible. Furthermore, it can be fitted to operate with sustainable materials, thus adapting your business to the new developments related to the sustainability of packaging solutions.

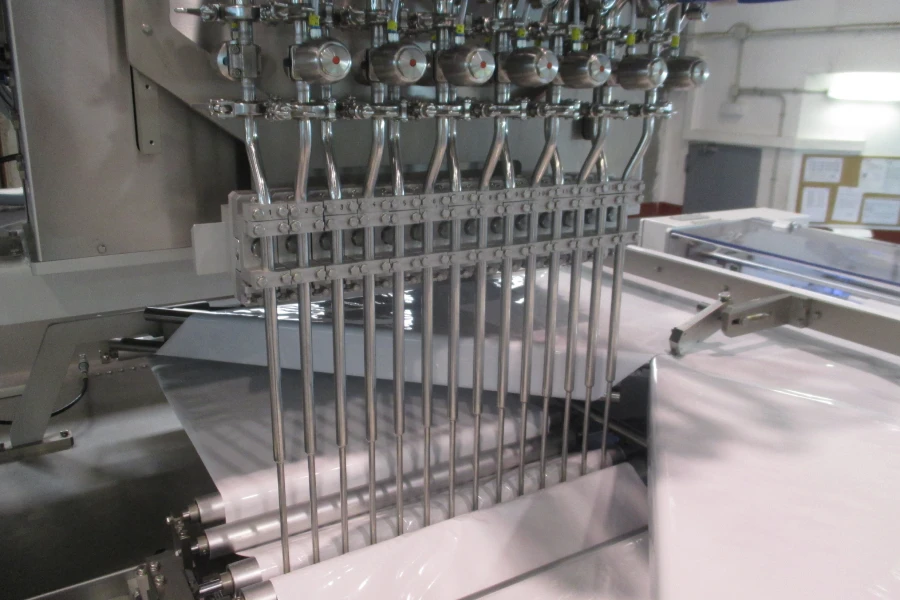

Up to 5 filling stations are available to increase solution flexibility depending on pouch height and available space.

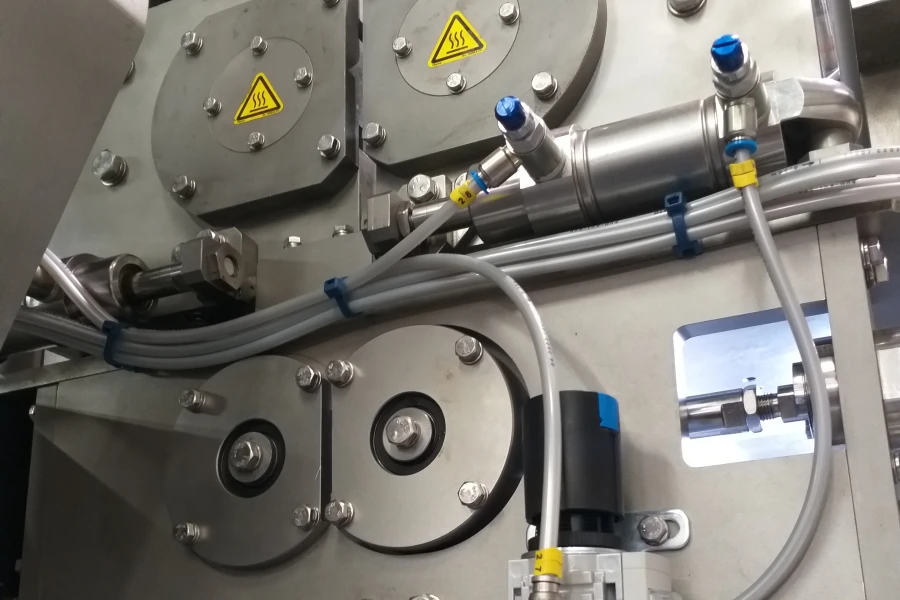

The forming area includes a continuous sealing station allowing to producer longer pouches with bigger quantities of product inside.

The forming area of our ML Series allows to make easily the format changeovers, as a result of its mobile support design. Futhermore, such the triangle position as the eyemark sensor are controlled directly by HMI.

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.