Automation is highly valued in our solutions. We believe it is one of the most important processes which assists you in reducing machine downtime and increasing production. At Mespack, we have integrated the concept of automation into various parts of our machines, such as an automatic changeover, a quick changeover, and an autosplice unwinder.

Automatic changeover system is compossed of:

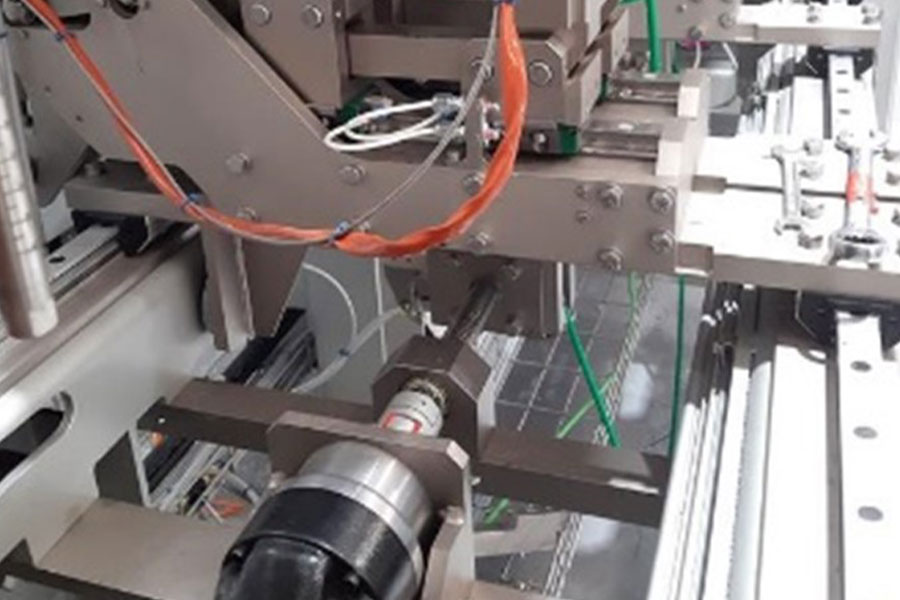

The Quick Format Change Revolver system consists of a positioning bar, which is parallel to the longitudinal guide and has position preconfigured jaws for each pouch format. To change the format, it is necessary to release the sealing group, set the guide in the position corresponding to the new forma,t and refix the sealing group by attaching the retainers in the defined position. This system allows a fast format change without the need to make other adjustments.

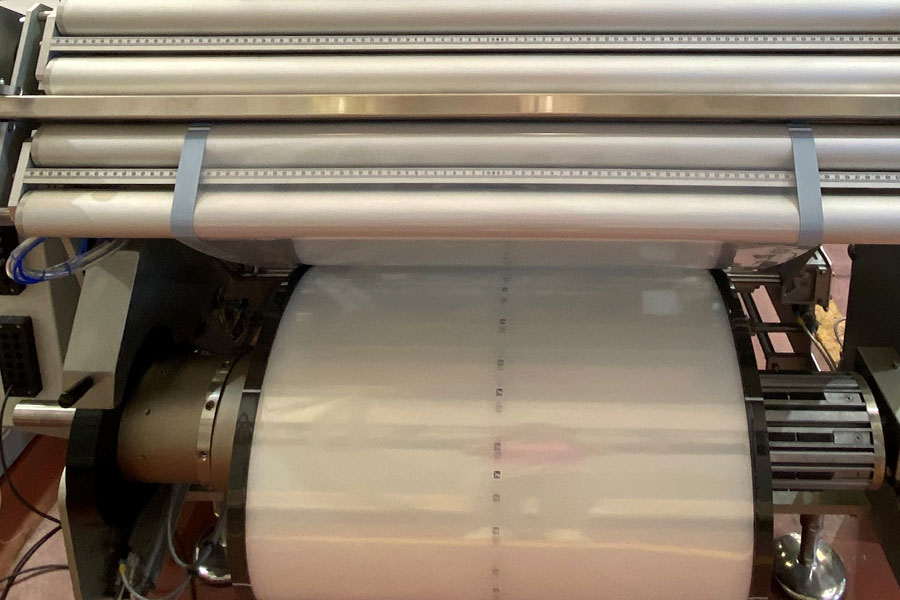

The automatic reel splicing system integrates the Butler device, which automatically splices the final section of the finished reel with the initial section of the new reel, thus avoiding production stops in order to perform this process. Manufactured in a structure with support for two reels, the Butler device is located on the reel splicing table, between the upper and lower reel.

CORPORATE HEADQUARTERS

C/ Mar Adriàtic, 18

Pol. Ind. Torre Del Rector

08130 Santa Perpetua De Mogoda

Barcelona – Spain

info@mespack.com

Learn about the largest product portfolio of the industry for innovative packaging

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.