- The Duravant Group company will make good use of attending the trade fair by presenting its new commercial tool which makes it possible to see large-scale equipment in operation without having to physically transport it.

- Ever loyal to the Asian event, the flexible packaging solutions manufacturer also wants to consolidate its presence in this rapidly growing market and identify new consumer trends.

- Mespack will attend its customers at stand AC22 in the BITEC centre in Bangkok.

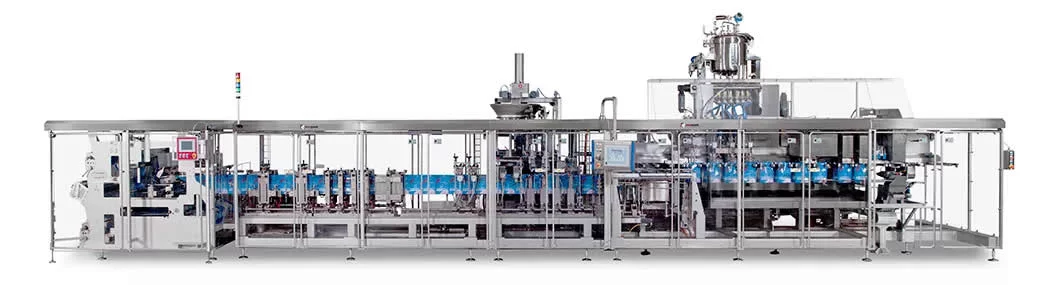

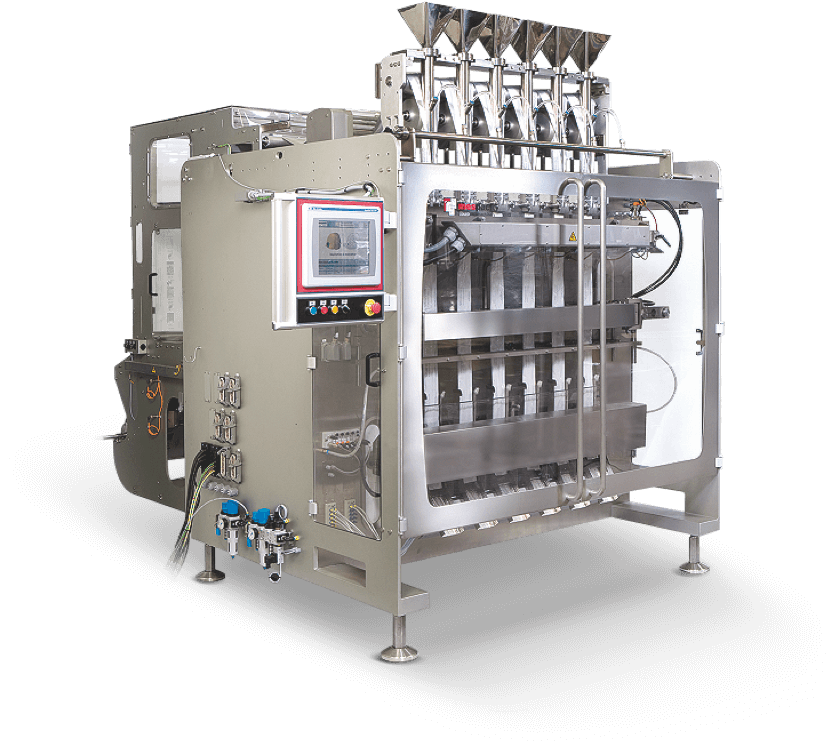

In recent years, Asian countries have experienced a large increase in the consumption of flexible packaging, which has translated into increasingly large interest on behalf of manufacturers in multilane packaging machines for stick pack, flat sachets and pre-made pouches like the Mespack MS-ML and SC series offer. This is why the Duravant Group company will not miss its annual meeting with ProPak Asia. The exhibition, which will be held on 12-15 June in the Bangkok International Trade & Exhibition Centre (BITEC) in Bangkok, Thailand, will therefore become the best showcase in SEA for Mespack’s wide catalogue of solutions. Furthermore, this year Mespack will attend the event with its virtual reality glasses.

“ProPak Asia is a vital event on our calendar. Asia is an expanding market, in which the demand for stick pack formats is on the rise, especially in the liquids sector (food and homecare). Our horizontal machines continue to win over manufacturers in the Asian market. Last year in Asia, for example, we sold two HCM-420-FED machines, a continuous packaging solution for large-scale production of stand-up pouch and high-volume Doypack varieties. Our clients were convinced by its reliability, efficiency and robustness, but above all, by the fact that it allows them to make up to 11 format changes in an easy and completely automated way. With the press of a button, the machine would change the position of all parts in the forming and dosing zones”, Santi Alberich, the company’s Marketing Manager explains. He also points out that Mespack continues to work to improve the design of its machines “so that there is even less operator intervention during format changes. We will soon launch the first changes,” he confirms.

Mespack will attend its customers at stand AC22 in the BITEC centre in Bangkok.

Innovative tools for versatile solutions

Asian manufacturers increasingly choose the most versatile equipment possible, -“they ask for solutions which allow the highest number of formats possible with the shortest amount of time taken to make changes possible”, Alberich confirms-. Something which, without doubt, Mespack’s solutions offer, and which can be proven using virtual reality at its ProPak Asia stand.

“In fact, this year we will attend ProPak Asia with our new commercial tool. Virtual reality glasses, exclusive to Mespack, which allow us to teleport our clients to our factory to get an on-site view of the different technical solutions we offer. These are not typical virtual reality glasses, they show a 360º stereoscopic vision of our equipment, so that whoever uses them feels that they are watching the machines in operation as if they were physically in our factory”, outlines the company’s Marketing Manager. “Mespack’s glasses are a very powerful commercial tool”, Alberich continues, “because they allow the client to be guided through the pouch production process, from the reel (or the feeding belt in the case of the SC-Series) to the sealing of the pouch”, he adds.

This revolutionary application will allow them to see how the previously mentioned HCM-420-FED, as well as the H-540-FE6, function. The latter is a high capacity packaging machine which can produce between 300 and 360 small-format (120-200 ml) stand-up pouches per minute, with a choke-proof top cap and rounded edges. Both machines have a full range of equipment which can be transferred to smaller machines.

Finally, Alberich reminds us that ProPak Asia will also provide a new opportunity to consolidate Mespak’s presence on the Asian continent: “We want to continue being instrumental in this expanding market, therefore we will make the most of our presence in Thailand in an effort to reinforce relations with our representative in the area, as well as to monitor the evolution of new trends at first hand and to identify needs in order to put our R+D department on the right path”, he concludes.

About Mespack: Mespack is an international manufacturer of flexible packaging solutions which designs and manufactures high-efficiency and high-speed machinery for leading consumer goods companies throughout the world. Based in Barcelona, the company, set up in 1994, has a broad portfolio of equipment with cutting-edge technology and specializes in the forming, filling and sealing of 4 sided sealed sachets, stick packs, stand-up pouches and other flexible packaging solutions for the food and drink, pharmaceutical, chemical, confectionery, cosmetics and personal care industries.

Mespack joined the Duravant Group in 2015 and currently has a workforce totalling 180 employees and 25 highly-specialized engineers and designers. With more than 1,500 machines in operation around the world, it provides excellent export management, with a sales network in more than 70 countries and regional centres facilitating rapid access to spare parts and services.

More information: www.mespack.com

About ProPak Asia 2019: ProPak Asia 2019 will take place 12th to 15th June at Bangkok International Trade Exhibition Centre (BITEC), Thailand. The show is returning in its 27th installment as the largest industry event of its kind in Asia with the theme of ‘The Future of Processing & Packaging Innovation’, showcasing new machine and technology from over 2.000 exhibitors from more than 60 countries.

More information: www.propakasia.com