Forming section

Liquids

Solids

Granules

Powders

Exit section

Unwinder section

Reject section

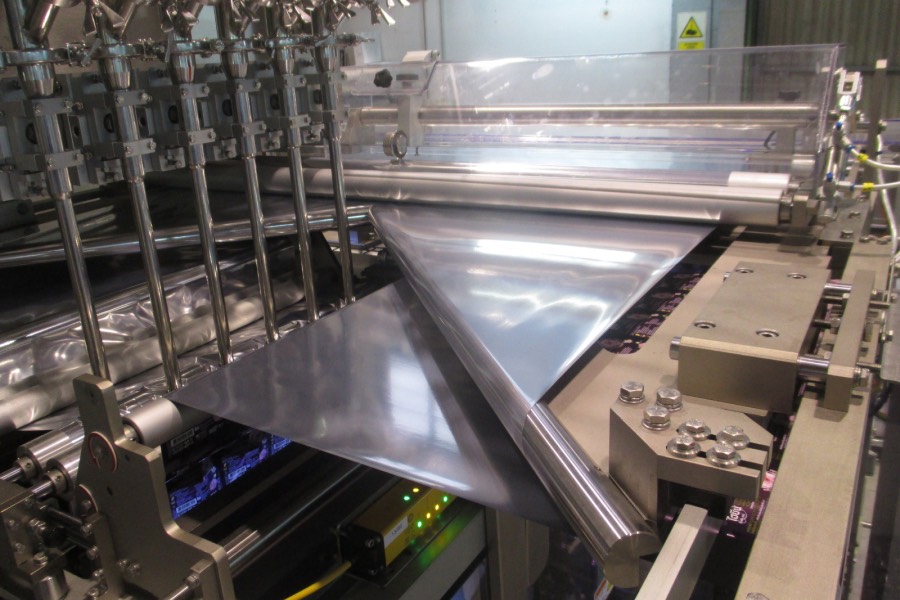

Forming section

Liquids

Solids

Granules

Powders

Exit section

Unwinder section

Reject section

The ML-Series is offered in two different models, the ML1000 and ML1200. Both have between 4 and 14 lanes available. The ML Series is especially suited for a multitude of products, granules, powders, and liquids. It is widely used in pharmachuetical, food, as well as the home and personal care sectors. Additionally, we offer automatic downstream equipment, such as conveyors, pick and place robots, as well as cartooning facilities. These 4 side seal sachet packaging machines, have the most recent motion technology with integrated PLC functions, which sequences 7 brushless motors.

The forming area of our ML Series allows to make easily the format changeovers, as a result of its mobile support design. Futhermore, such the triangle position as the eyemark sensor are controlled directly by HMI

Servo motor is integrated into the film transport system in order to control and correct its position. This system has more operational precision, and gives you more coordinating control of the equipment’s movements.

To archive a Total Productive Maintenance design, our sealing system can easily be opened to perform a cleaning operation. Moreover, all driving units are inside the frame, in order to avoid product contamination.

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.