In today’s competitive manufacturing landscape, packaging operations face growing pressure to increase efficiency, minimize errors, and maintain compliance with evolving industry standards. Product variability, short changeover times, and manual interventions can all impact productivity and profitability.

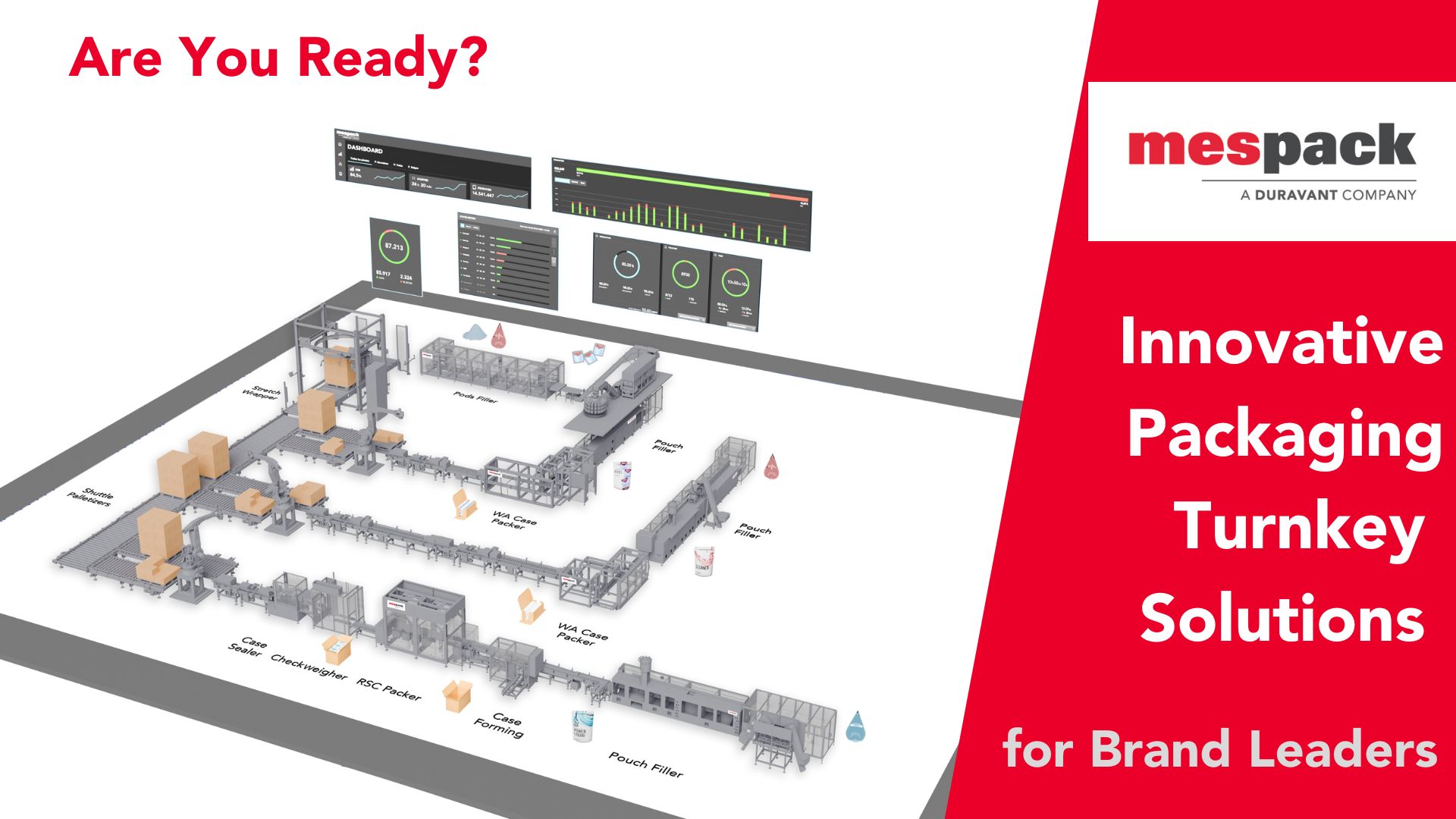

An integrated, turnkey approach to packaging provides a strategic solution—one that brings together design, technology, and project management under a unified system. By doing so, manufacturers can enhance operational performance, reduce risk, and accelerate time-to-market while ensuring consistency and flexibility across their production lines.

The Challenges of Modern Packaging Operations

Packaging environments today are more dynamic than ever. Brands strive to manage a wide range of products, materials, and formats, all while maintaining strict quality standards. Common challenges they face:

- Product variability: Different sizes, materials, and compositions demand rapid machine adjustments.

- Frequent changeovers: Shifting between SKUs reduces uptime and increases complexity.

- Manual errors: Human involvement in repetitive processes raises the risk of defects and compliance issues.

- Regulatory requirements: Traceability, hygiene, and safety compliance must be maintained consistently.

Meeting these challenges requires more than equipment upgrades—it calls for a holistic system that integrates technology, workflow, and data monitoring for greater reliability and control.

The Value of Integration in Packaging Systems

Integrated packaging systems align every component—from filling and sealing to cartoning and palletizing—into one synchronized ecosystem. This interconnected approach delivers several operational benefits:

- Improved efficiency: Automated coordination between machines reduces idle time and maximizes throughput.

- Enhanced quality control: Centralized monitoring ensures consistent sealing, labeling, and product handling.

- Error reduction: Automation minimizes manual intervention, improving repeatability and compliance.

- Simplified operations: Unified interfaces and controls make training, maintenance, and troubleshooting more efficient.

Ultimately, integration helps manufacturers achieve higher output with fewer resources, while maintaining the agility to adapt to new market demands.

Centralized Project Management and Early Validation

A key strength of turnkey solutions lies in centralized project management. Instead of coordinating multiple suppliers and timelines, manufacturers benefit from a single point of contact overseeing the entire process—from design to installation.

This unified oversight ensures:

- Seamless communication between machinery suppliers and process teams.

- Transparent scheduling and resource allocation.

- Minimized risk of errors caused by fragmented coordination.

Moreover, factory acceptance testing (FAT) at the supplier’s facility enables early validation of the complete line. Manufacturers can test performance, detect integration issues, and fine-tune parameters before installation—significantly reducing startup time and unplanned downtime.

Scalability, Flexibility, and Future-Proofing

An effective packaging system must evolve alongside a manufacturer’s business. Modern turnkey solutions are designed to scale production capacity and adapt to new product requirements without operational disruption.

- Scalability: Modular design allows easy capacity expansion as production grows.

- Flexibility: Machinery accommodates new packaging formats or materials, including recyclable and paper-based laminates.

- Future-proofing: Industry 4.0 connectivity, remote monitoring, and predictive analytics prepare lines for future automation and digital integration.

This adaptability ensures long-term return on investment and keeps manufacturers competitive in rapidly changing markets.

Digital Integration for Smarter Operations

The integration of digital technologies within turnkey packaging systems enhances both visibility and control across operations.

- Real-time monitoring of production metrics enables proactive decision-making.

- Predictive maintenance tools identify potential failures before they occur.

- Data traceability supports compliance with quality and regulatory requirements.

By combining digital insight with automation, manufacturers can achieve a new level of operational intelligence—reducing risk, improving uptime, and supporting continuous improvement initiatives.

Sustainability and Compliance from the Start

Sustainability and compliance are no longer optional—they are strategic imperatives. Turnkey solutions address both from the earliest stages of design by incorporating:

- Energy-efficient equipment and optimized resource utilization.

- Automated precision that reduces product and material waste.

- Built-in compliance controls aligned with industry regulations and certification standards.

Integrating sustainability and compliance into the planning phase positions manufacturers to meet corporate and regulatory objectives without compromising production efficiency.

Conclusion: A Smarter Way to Package Success

Turnkey packaging solutions transform the way manufacturers design, build, and operate their production lines. By combining integrated machinery, centralized project management, digital monitoring, and sustainability-driven design, companies can overcome operational challenges, reduce risk, and bring products to market faster. Learn more about practical implementations on Turnkey Solutions.

As the packaging industry continues to evolve, those who embrace integrated turnkey systems will not only optimize performance but also position themselves as leaders in efficiency, innovation, and reliability. Discover how Turnkey Solutions can optimize complex packaging operations for maximum strategic impact.