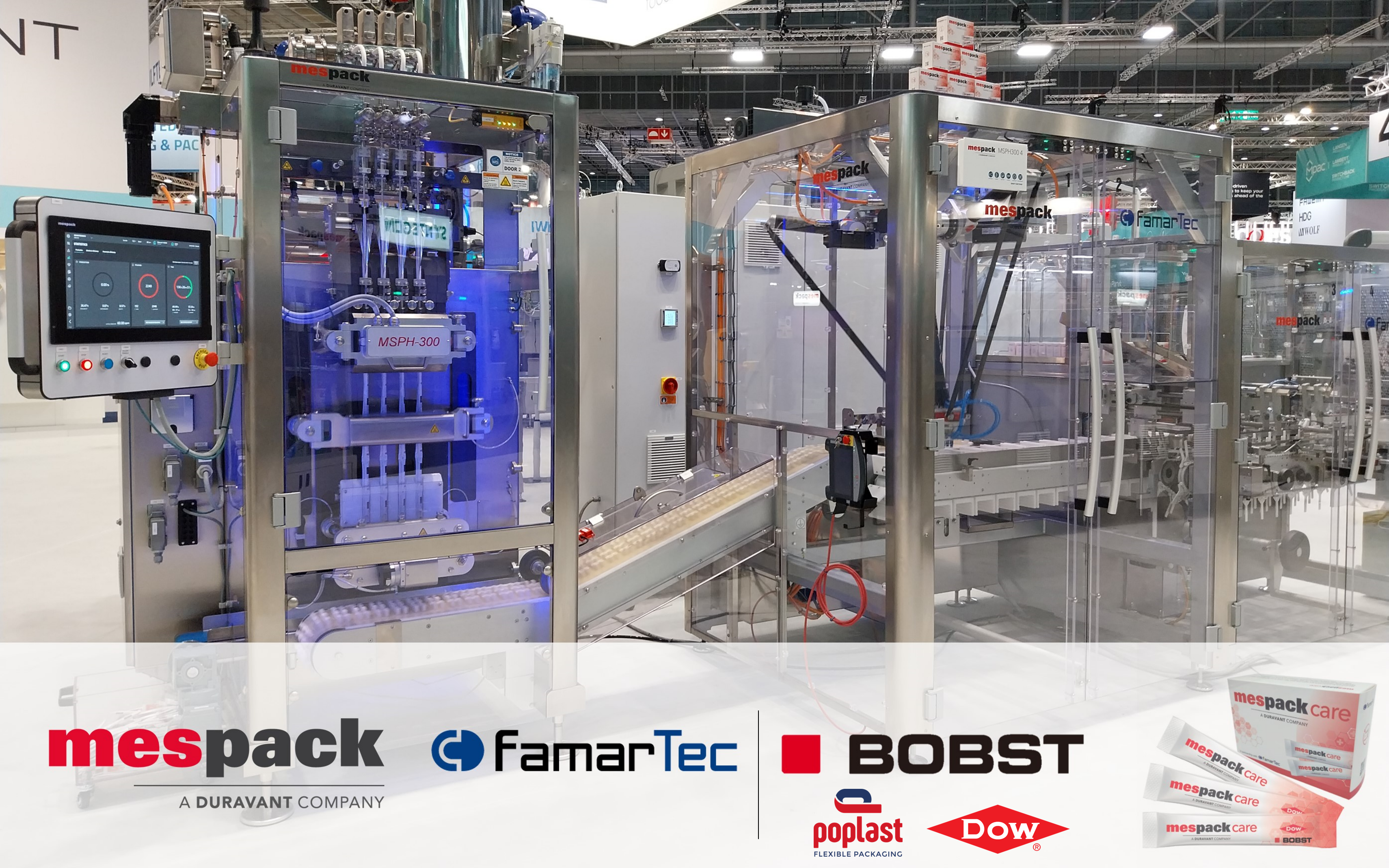

- Mespack’s new vertical form-fill-seal machine, exclusively developed for pharmaceutical products, is integrated with Famartec’s cartoning machine, in order to produce stick packs and insert them into cartons offering a Turnkey Solutions

- This the vertical form-fill-seal machine, for pharmaceutical products packaged in stick packs, is able to produce up to 840 sticks per minute.

- Ready to work with oneBARRIER recyclable ready mono-material laminate based on a metalized MDOPE film and high-performance sealant web, developed by BOBST and DOW, and printed by POPLAST.

Mespack, a leading manufacturer of innovative and sustainable flexible packaging solutions, showcased at Interpack, the most compact Mespack vertical stick-pack machine. This new solution, the MSPH, is focused on the pharmaceutical industry.

The MSPH series is an innovative solution that has been developed in collaboration with our partners Farmatec (secondary packaging) and Bobst (stick pack film) in order to offer a high-quality integrated solution for this sector. The solution integrates primary and secondary packaging in one equipment. The growing demand from pharmaceutical customers for a complete solution to address their production needs, encouraged them leading machinery manufacturing companies to join forces in order to respond to the market.

This joint project consists of a new vertical form-fill-seal machine for the production of stick-pack sachets. The MSPH series is integrated into a cartoning module that groups the sachets before inserting them into the carton.

The MSPH series from Mespack has been specially designed for the pharmaceutical industry, and complies with specific regulations, such as GMP, GAMP5, FDA, and 21 CFR Part 11. In reference to documentation focused on pharmaceutics, this solution not only offers the execution of DQ, IQ, OQ, RA, but also the preparation of PQ and EN1020 standard 2.1 and 3.1 material certificates. Upon request, other forms of documentation can be prepared as well.

This vertical form-fill-seal machine, designed for pharmaceutical products in stick packs, is able to produce up to 840 sticks per minute with MSPH600. The primary features of the vertical stick product are:

- Full Servo and Stainless-Steel Machine: It is made of stainless steel in order to operate with pharmaceutical products. This machine is integrated with the full servo motorized system which gives

tothe customer more coordinated control of the equipment movements. - Protocol DQ/IQ/OQ/PQ: Regarding pharmacy orientated documentation, we offer the execution of DQ, IQ, OQ, RA, the redaction of PQ, and all other forms of documentation (upon the requirement of the customer).

- Artificial Vision Cameras (optional): The new Mespack transfer is specially designed in order to increase production speed by up to 30%.

- Individual Exit Chute (optional): This vertical machine has an individual exit chute with

arejection possibility. As a result, there is less material waste for the client.

Jaume Roquet, solutions and project director at Mespack, states: “The pharmaceutical sector is increasingly demanding integrated solutions and new formats for medicines. As a result, we are very proud of our collaboration with Famartec, which has culminated in the development of a high-quality solution for an industry that must meet the needs of a growing and increasingly demanding market.“

In this case, Mespack, with the collaboration of Bobst, Dow and Poplast, has create a stick pack with a oneBARRIER recyclable ready mono-material laminate based on a metalized MDOPE film and high-performance sealant web, developed by BOBST and DOW, and printed by POPLAST. That collaboration has allowed the new MSPH Series to work with recyclable material.

In reference to Mespack’s commitment to offer the pharmaceutical sector a complete solution to meet its primary and secondary packaging needs, the company guarantees the perfect synchronization and compatibility of all line elements. Furthermore, in addition to having the broadest portfolio of products on the market, Mespack has the technology and most qualified team to achieve success as well.

Mespack has the largest product portfolio of the industry, which offers horizontal (including roll-stock, pre-made, and hybrid), vertical, and water-soluble pods equipment to produce sachets, stick packs, stand-up pouches, film-based packaging, and end-of-line solutions.