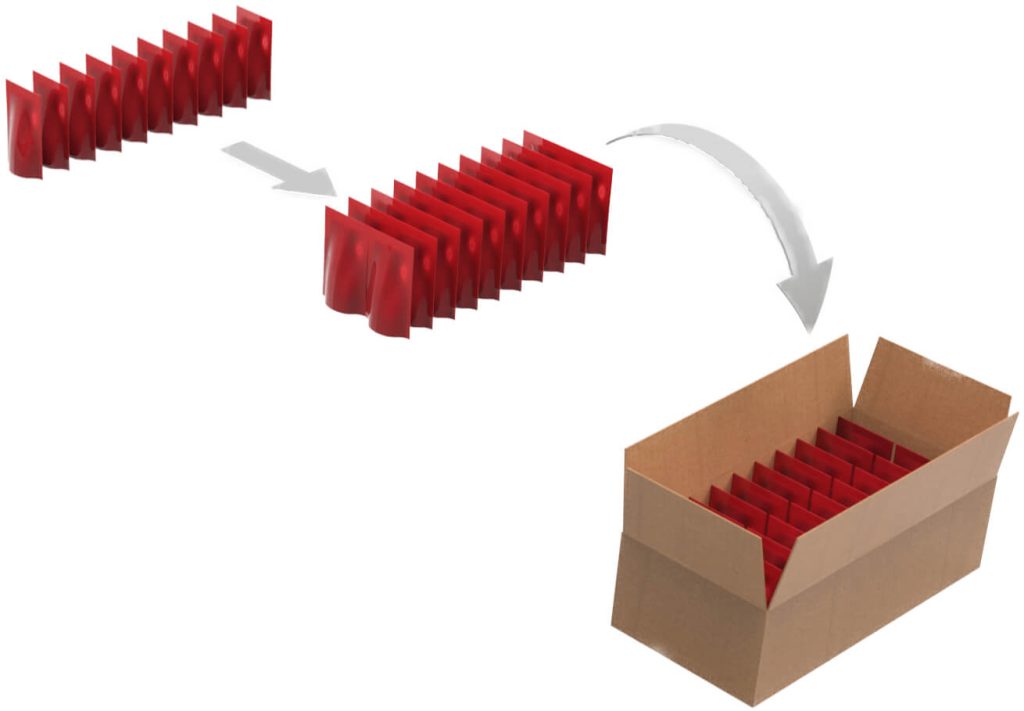

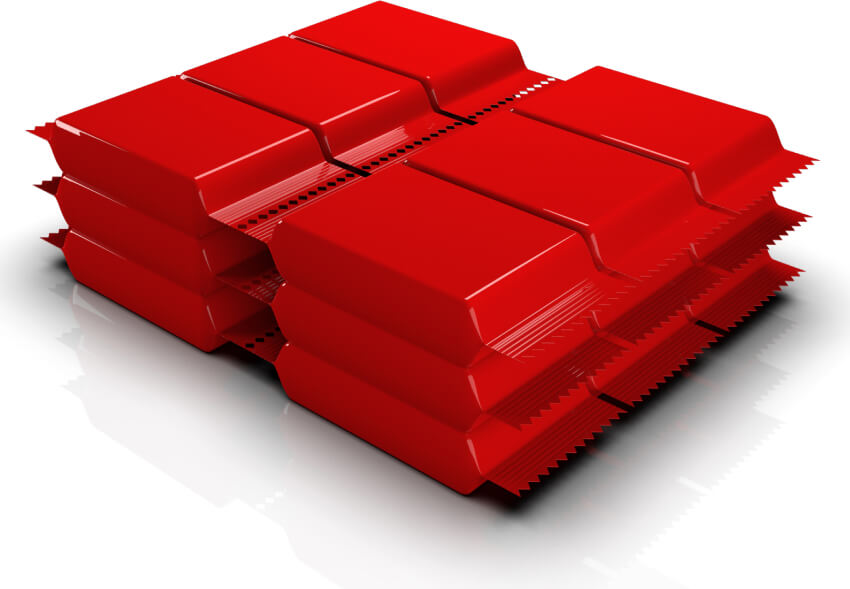

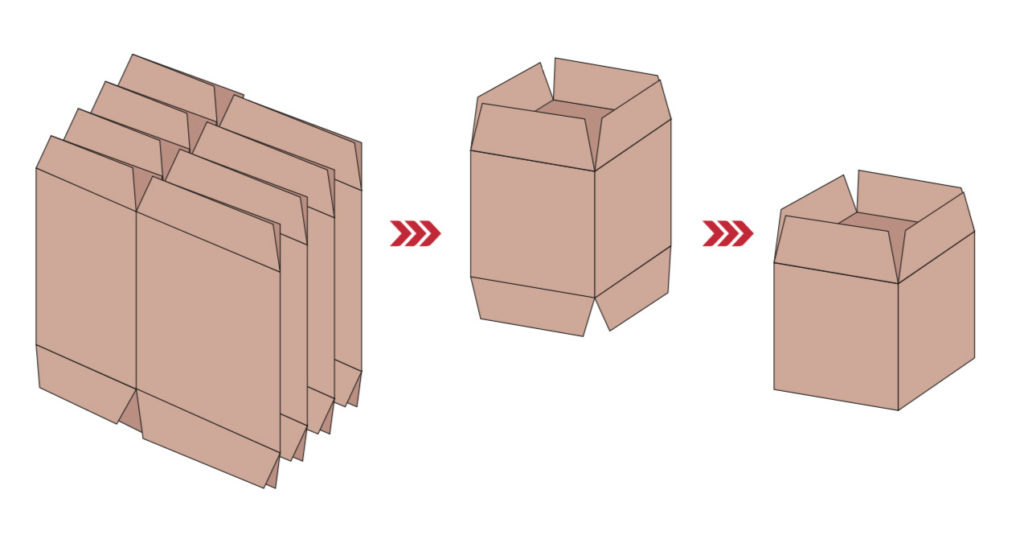

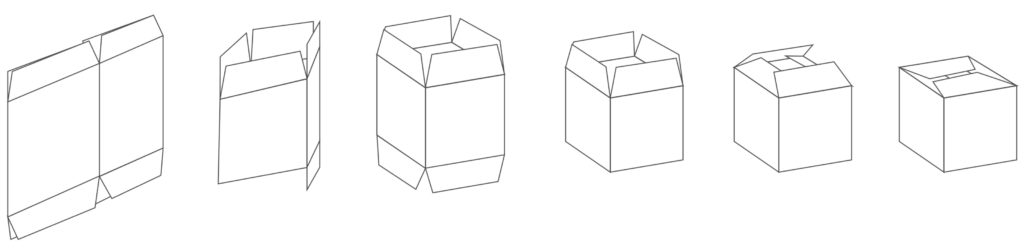

At Mespack, we provide Turnkey projects of flexible packaging into the market. One of our solutions is the American box packing module EF100, which consists of three equipment connected in one: case erector, picking, and case sealer. The flexible pouches can be grouped horizontally or vertically inside the boxes, and the maximum speed is up to 20 cases per minute.