Pods are the fastest-growing packaging format in the home care sector. They currently account for 11% of the laundry detergent market. Water soluble pods are one of the trendiest and fastest growing Consumer Packaged Goods (CPG)/Fast-moving Consumer Goods (FMCG) categories.

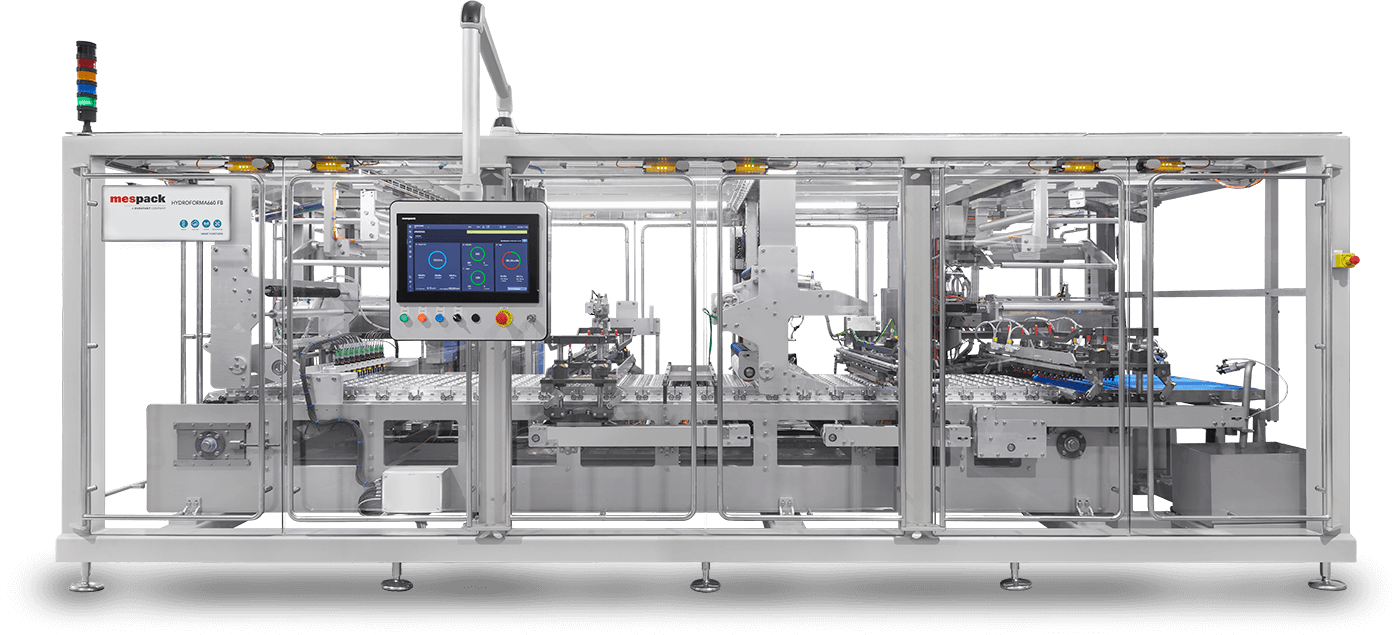

This innovative format was pioneered by Mespack and our revolutionary Hydroforma FB Series, which is comprised of high-speed water soluble pod machines. With speeds up to 2000 pods per minute, our new Hyfrodorma FB Series is the last innovation that combines HFFS technology with water-soluble technology that allows us to leverage our expertise in both areas for maximum efficiency and innovation.

The Mespack Hydroforma FB Series is also the leader in sustainability; it produces less waste than other leading brands in the market.

In harmony with its easy usability, this Series of machines continues to use the Athena platform, with which the operator can monitor, simultaneously, the OEE ratio as well as the ratio of rejected pouches, among others.

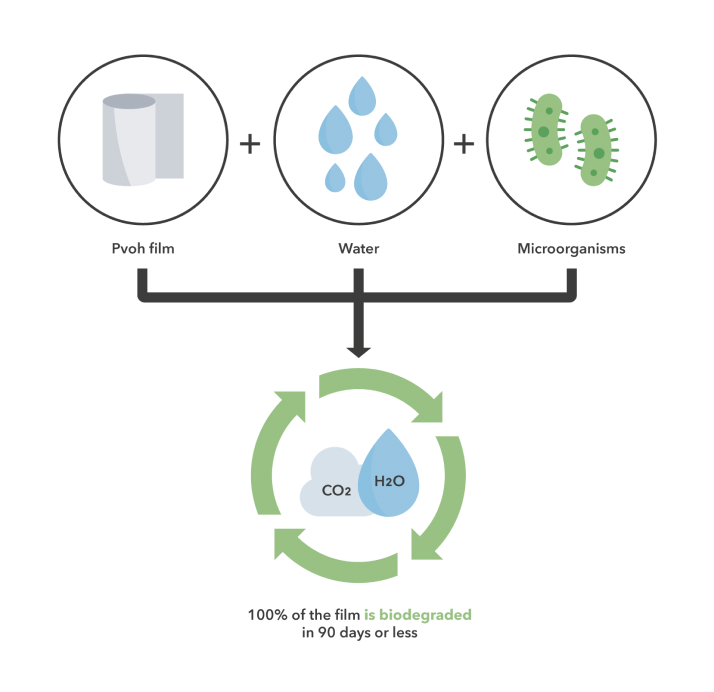

Polyvinyl Alcohol (PVOH) and edible film are used to produce pods. According to American Cleaning Institute, at least 60% of the film biodegrades within 28 days, and 100% of the film is biodegraded in 90 days or less.

The Hydroforma can simultaneously load powders and/or liquids. The high precision, servo-driven product management features give an accurate assurance of your desired product amount.

It is a servo-driven unit with blades that move up and down. This makes them a safe cutting system and facilitates the separation of the strings into individual pods.

The pods are transferred to a conveyor belt by individually controlled vacuum suction cups. The film trimmings waste is removed by a suction system that is located on both sides of the conveyor belt.

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.