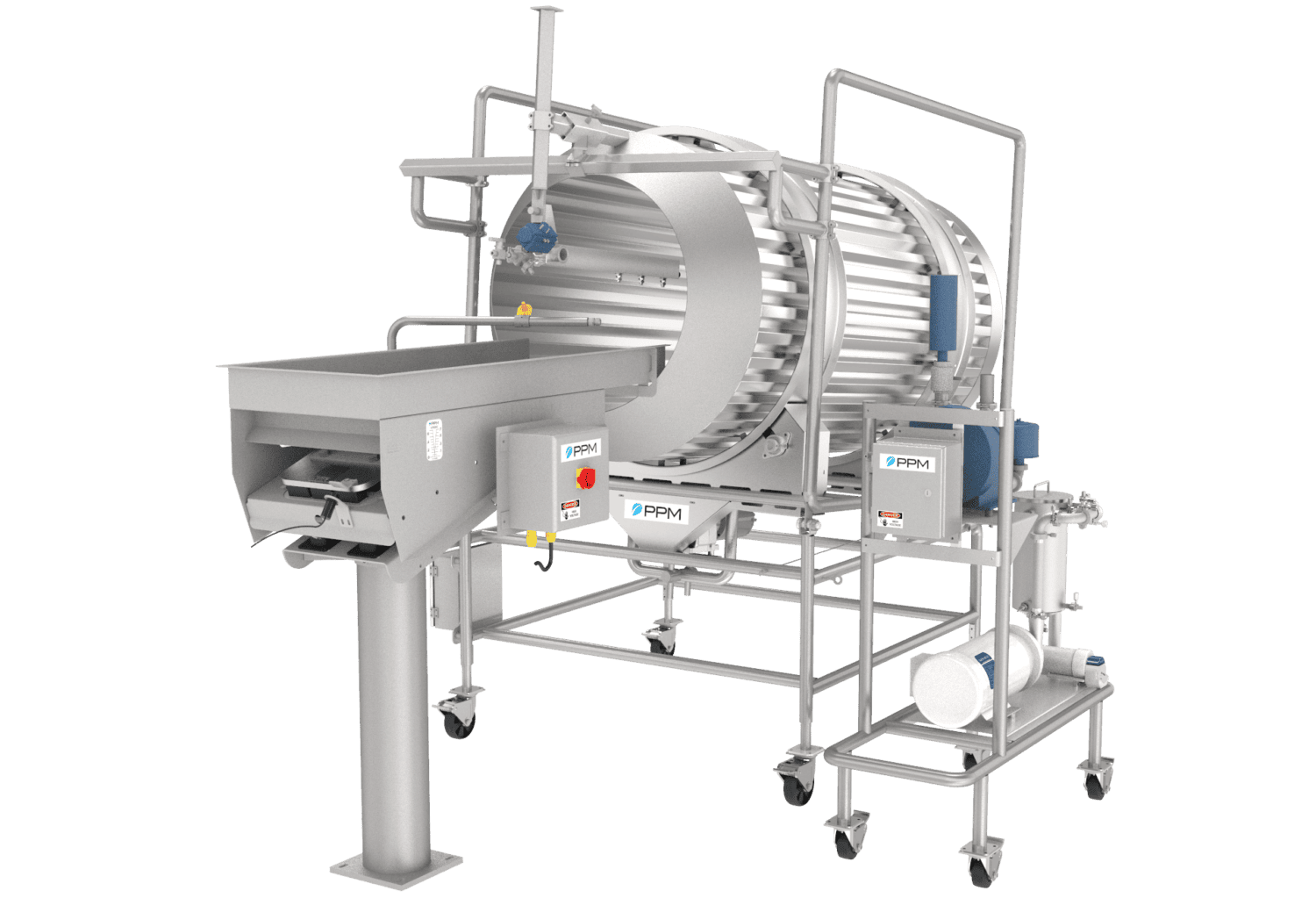

PPM Technologies is a global automation solutions provider of smartly engineered equipment and integrated lines for the food processing industry. PPM designs, engineers and manufactures equipment for a wide array of food products including snack foods, cereals, confectionaries, nuts and seeds, vegetables, meats, poultry, seafood and more.

Their portfolio includes conveying, coating, grading, frying and cooling equipment that can be customized to integrate with virtually any production line. PPM has combined passion and expertise to provide uniquely engineered solutions with new and innovative products designed to improve quality, increase efficiencies, and reduce costs.

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.