Mespack’s machine packaging fillers are designed to adapt our HFFS and VFFS machines to a wide variety of different fillers in order to obtain free and non-free flowing products, a variety of liquid thickness, pieces, and numerous other products.

Magnetic Inductive Flowmeter Bopp & Reuther Mass Flowmeter Endress Hausser For conductive liquids and pasty products composed of: Pressurized hopper of 80 litres capacity made of sanitized 316 stainless steel including a two-way valve for product return Electronically controlled inductive measuring system that actuates directly on the filling nozzles Sanitized nozzles made of 316 stainless steel with pneumatic product cut-off system Electronic independent control box with alpha-numeric display to pre-set fill doses and statistical display of all necessary data Filling accuracy +/- 1%

This system is used to fill free-flowing products by volume.

It is composed of a stainless steel hopper that contains the products, which flow by gravity into a rotary plate with built-in cups. The cups are telescopic and allow a certain range of volume, i.e. 1 to 10cc, 20 to 40cc. Various interchangeable sets of cups are available. Two types of systems are available: a mechanically driven unit commanded by a cam and a motorized clutch/brake unit. Fillers can be either simplex or duplex.

This is a filling system for free and non-free flowing products as well as dusty and volatile products. There are two different versions of the auger filler: A/C motor with a clutch/brake system or D/C servo-motor. In both cases, the fill dose is pre-set in a counter on the touch screen. When using a clutch/brake unit, the accuracy is approximately +/-1’5% for most products. When using a servo-motor, the accuracy and the stop position is always exact with no inertias. The accuracy is around +/-1 for most products. The auger fillers are available in simplex, duplex, triplex or cuadruplex versions.

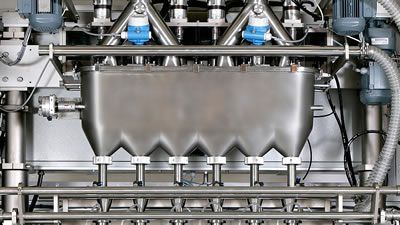

This type of filler is particularly relevant for thick and pasty products. The pump is composed of a 20 litres hopper made of stainless steel connected to an electrovalve. The electrovalve is synchronized with the filling machine through an electric signal, which enables a fill load to be done at each impulse. There are several pump sizes to cover fill doses from 1 to 250cc. The nozzles are customized according to the product characteristics and can be supplied with a suck-back or blow-off system. These filling pumps have various optional accessories as heated or pressurized hoppers for very thick products, hopper level detectors CIP facilities, etc.

This system is used for free flowing products that cannot be dosed using a conventional system, due to their characteristics.

The vibratory filler is composed of stainless steel vibratory bowls, which provide a continous flow of product into the vibratory channels which are synchronized to the machine cycle. Vibration intensity can be adjusted to the characteristics of the product.

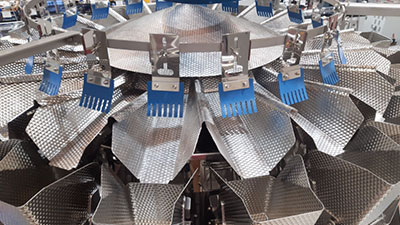

The multihead weight check can be used for free flowing solid products and is composed of:

Learn about the largest product portfolio of the industry for innovative packaging.

Data will not be stored

OEE

Data will not be stored

An edge computer, located in the machine cabinet, is responsible for collecting and sending data to the Cloud through a secure and encrypted internet connection that is stored and analyzed by Mespack Athena. All the data can be viewed from multiple devices. Worldwide, the customer can consolidate and view its machine data on a unique Mespack Athena dashboard.