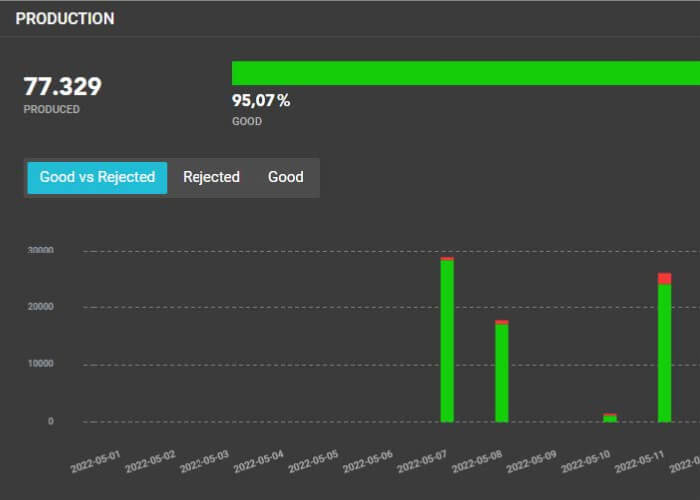

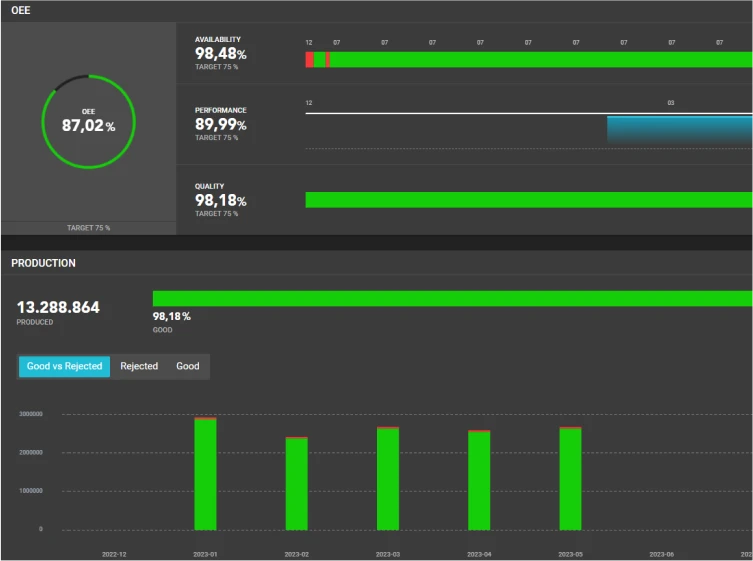

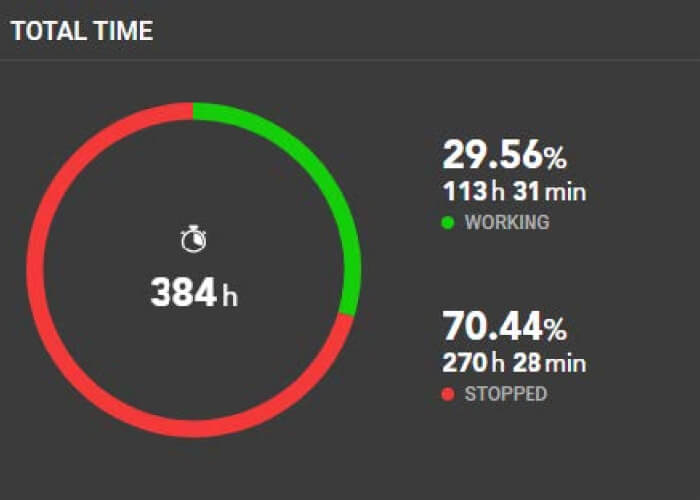

Increase Throughput Up To 4%

Increae in uptime and product ratio improvement represents a direct throughput enhancement, and subsequently optimizes equipment productivity.

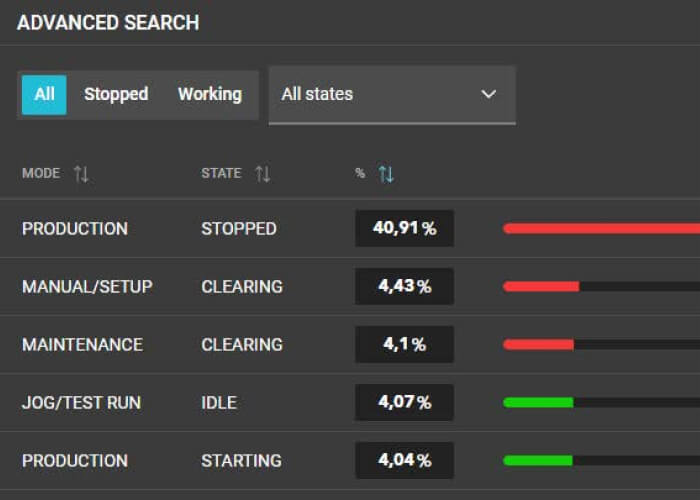

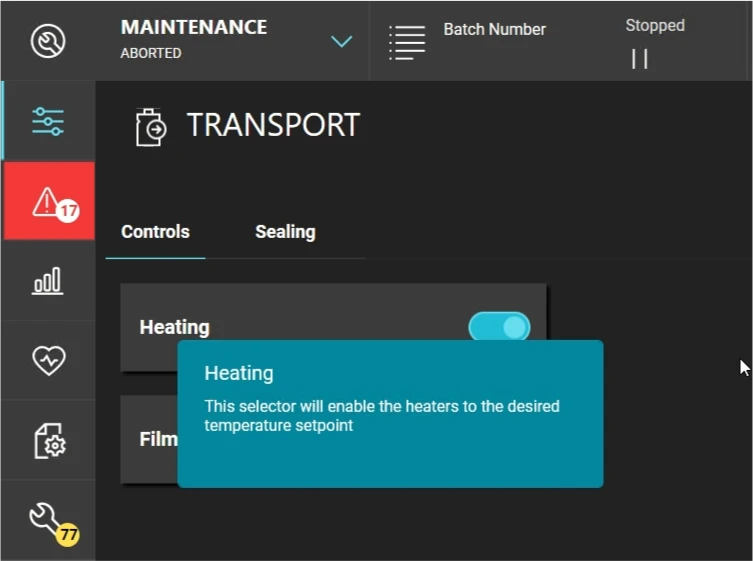

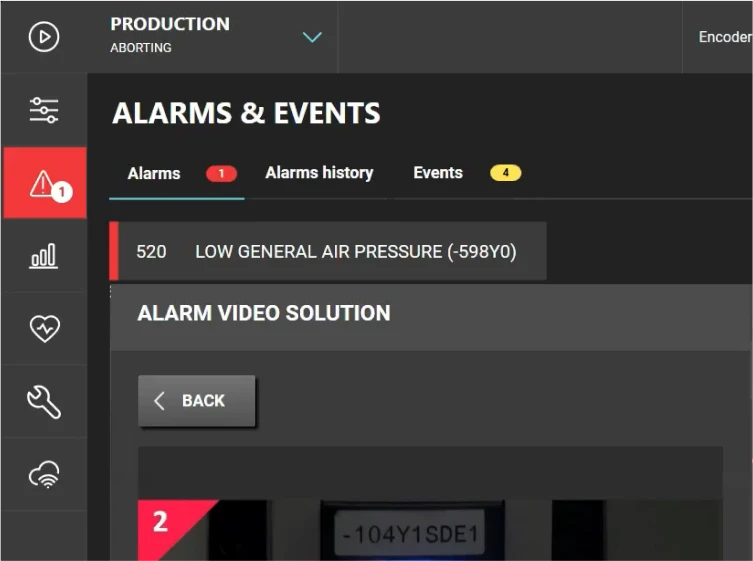

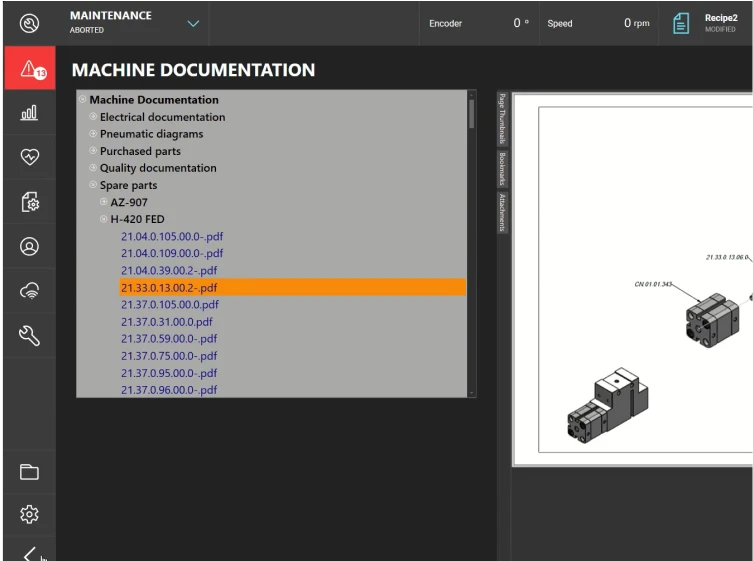

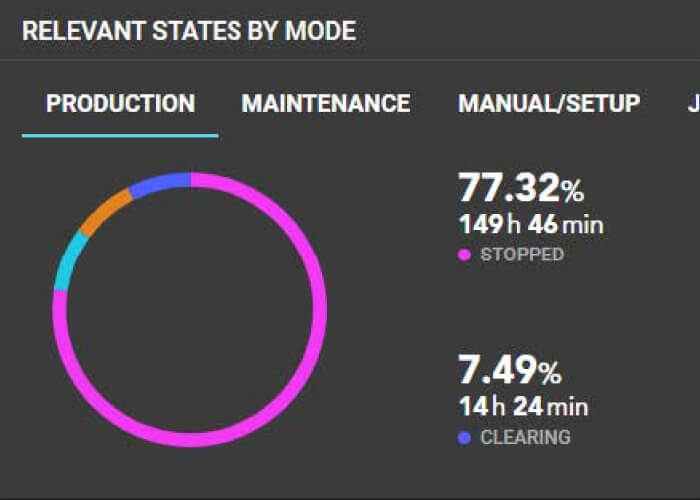

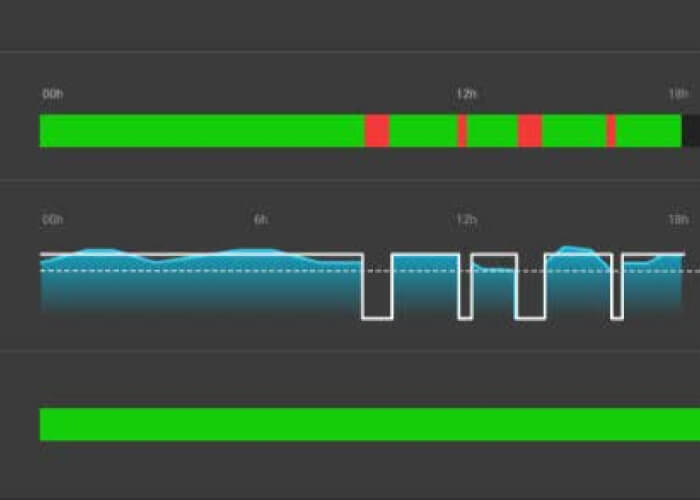

Cut Down Unplanned Downtime up to a 30%

Identifies the most frequent alarms and resolves the causes of downtime, which are responsible for 80% of machine downtime.

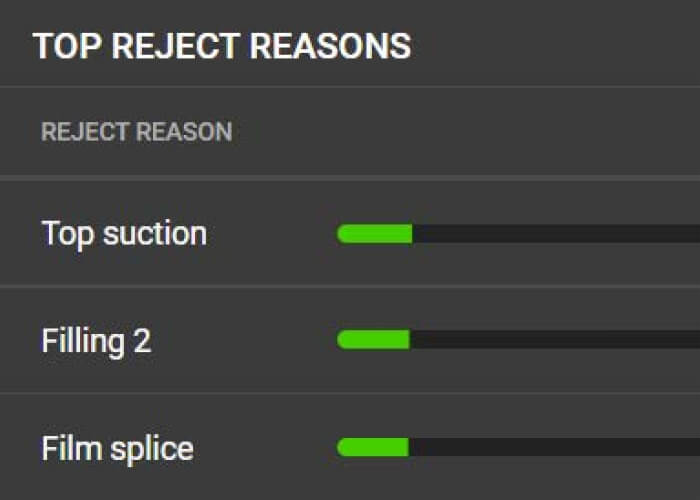

Reduce Reject Reasons Up To a 15%

Quickly addresses the most frequent causes of rejection, as well as the classifications of warnings and alarms, thus detecting those that affect quality.